When soldering with indium solder wire in high-temperature environments, several challenges arise, including: Oxidation Issues: Indium easily reacts with oxygen at high temperatures, forming oxides that can affect the quality of the solder joint and its electrical conductivity. Measures must be taken to reduce oxidation during the soldering process, such as using inert gas protection…

The use of indium foil in microchips is primarily due to several key properties of indium: Low Melting Point: Indium has a relatively low melting point of around 156.61°C. This allows indium foil to be melted and used for connections or soldering without damaging other microchip components. Excellent Ductility and Malleability: Indium has superb ductility…

Indium solder wire achieves the best welding results under the following circumstances: Low-Temperature Soldering Requirements: Due to the low melting point of indium solder wire, it is particularly suitable for applications needing low-temperature soldering to avoid potential damage to heat-sensitive components. Soldering Heat-Sensitive Materials: For heat-sensitive materials like certain plastics, rubber, or ceramics, the low melting…

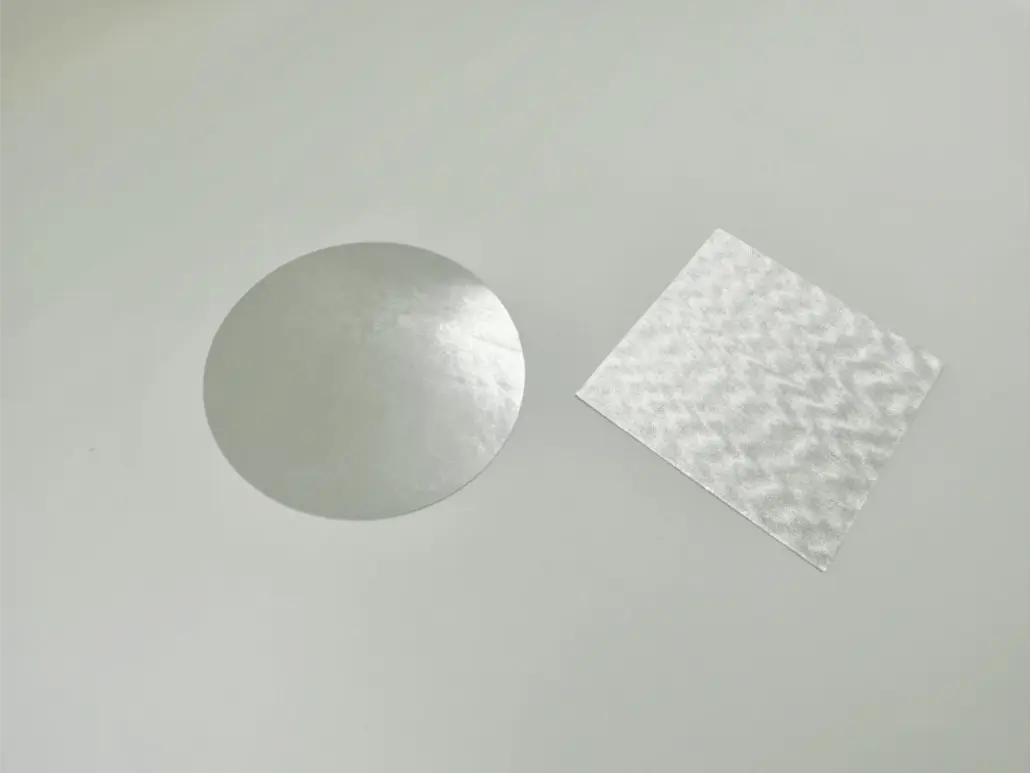

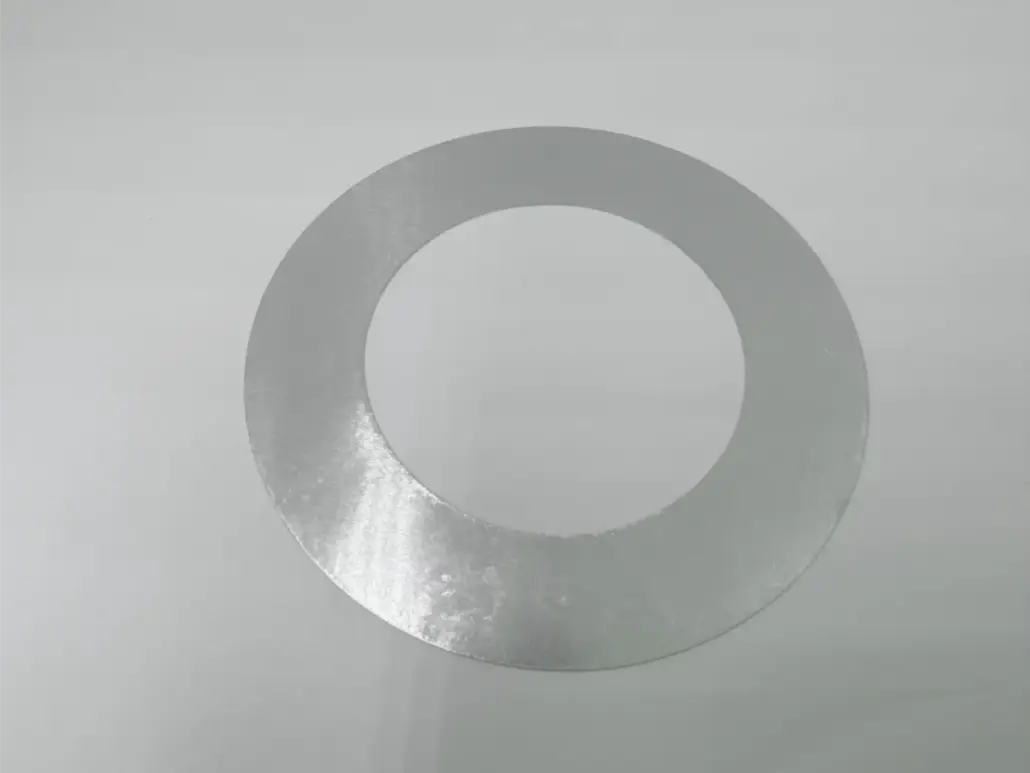

Product Name Features Applications Aluminum wire O-ring Aluminum wire O-rings with a purity of 99.99% and a diameter of less than 1mm need to be annealed at 350°C for 1 hour before use. Prior to usage, they should be cleaned with NaOH or dilute nitric acid. Due to the presence of an oxide film on…

Indium Vacuum Seal stands out as a superior material for creating helium-tight hermetic seals, bridging metals and non-metallic substrates like glass and ceramics. Its versatility extends to cryogenic environments, vacuum pumps, and heat-sensitive areas, where it ensures reliable containment. When indium serves as the sealant, it initiates a chemical bond with the surfaces it connects,…

When cryogenic and vacuum seals start to degrade over time, whether due to heat, thermal cycling, or constant pressure, they may need replacement to maintain functionality. If the device is still usable, the indium seal can often be renewed by following these steps: Disassemble the indium sealing, ensuring to carefully remove any remnants of the…

Indium solder wire is a versatile solution with a myriad of applications in electronic assembly, capitalizing on its distinct physical and chemical attributes. Let’s delve into its primary application areas: Sealing of Infrared Devices: Indium solder’s exceptional sealing capabilities make it indispensable in the production and packaging of infrared devices. By ensuring robust sealing, it…

Indium soldering wire, especially indium-containing solder materials, has a wide range of applications in various industries due to its unique physical and chemical properties. Here are some main application areas: Semiconductor Industry: Indium wire seal are widely used in the semiconductor industry due to their excellent thermal and electrical conductivity and low melting temperature. They are often processed into…

Indium solder wire is a type of low-melting-point indium alloy, mainly used for welding precision thermosensitive components and achieving full sealing. Aster offers three different types of indium solder wire, including In100 (100% indium), In97/Ag3 (97% indium and 3% silver), and In52/Sn48 (52% indium and 48% tin). In100 is pure indium, suitable for welding to…

Indium wire can be used for vacuum sealing applications due to its low melting point, malleability, and ability to create reliable seals. Here’s a basic procedure for using indium wire for vacuum sealing: Prepare the Surfaces: Ensure that the surfaces you want to seal are clean and free of any contaminants. This is crucial for…