Indium seal cryogenics involves the use of indium—a highly ductile and malleable metal—as a sealing material in cryogenic and vacuum applications. Discovered in 1863 by German scientists Ferdinand Reich and Hieronymous Theodor Richter, indium’s unique properties were initially overlooked until its ability to stabilize metalswas identified in 1924. Over the years, indium seals have become…

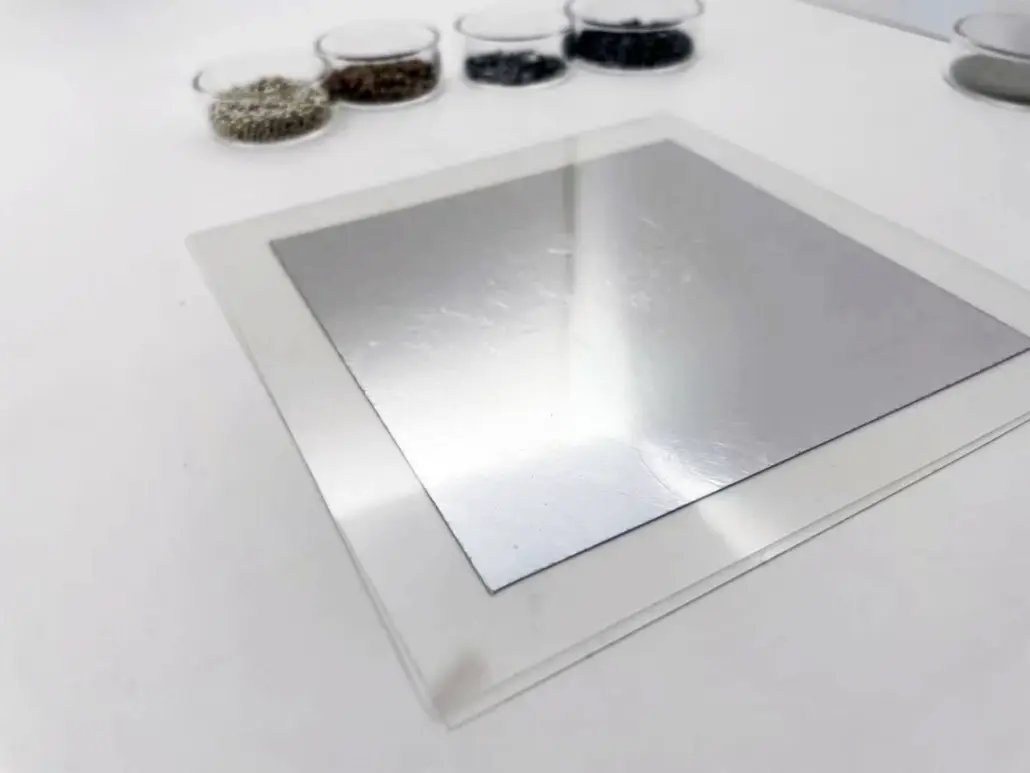

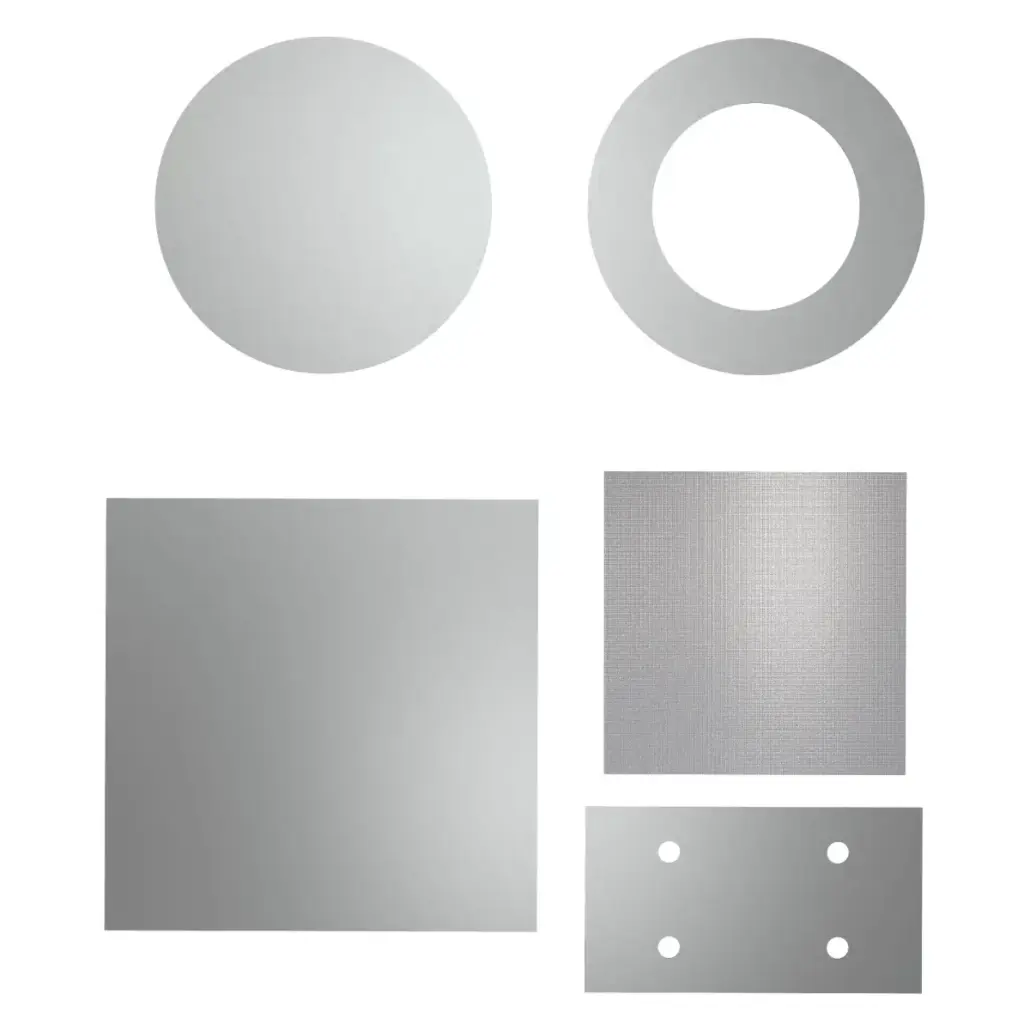

Indium foil is a thin sheet of indium, a chemical element with the symbol ‘In’ and atomic number 49, known for its exceptional physical and chemical properties. Indium is part of group 13 on the periodic table and is characterized by its softness, high plasticity, malleability, ductility, and remarkable corrosion resistance to water and alkalis,…

Indium foil cooling thermal pads are specialized thermal interface materials (TIMs) widely utilized in various high-tech industries for their exceptional thermal conductivity and unique physical properties. Indium, a soft, malleable metal discovered in 1863 by Ferdinand Reich and Hieronymous Theodor Richter, exhibits a low melting point and excellent thermal performance, making it a valuable component…

Indium foil is a highly specialized material used predominantly as a thermal interface material (TIM) in Central Processing Units (CPUs) due to its exceptional thermal conductivity and unique physical properties. Characterized by its softness, malleability, and low melting point of 156.6°C (313.9°F), indium foil effectively facilitates heat transfer between the CPU and its heat sink,…

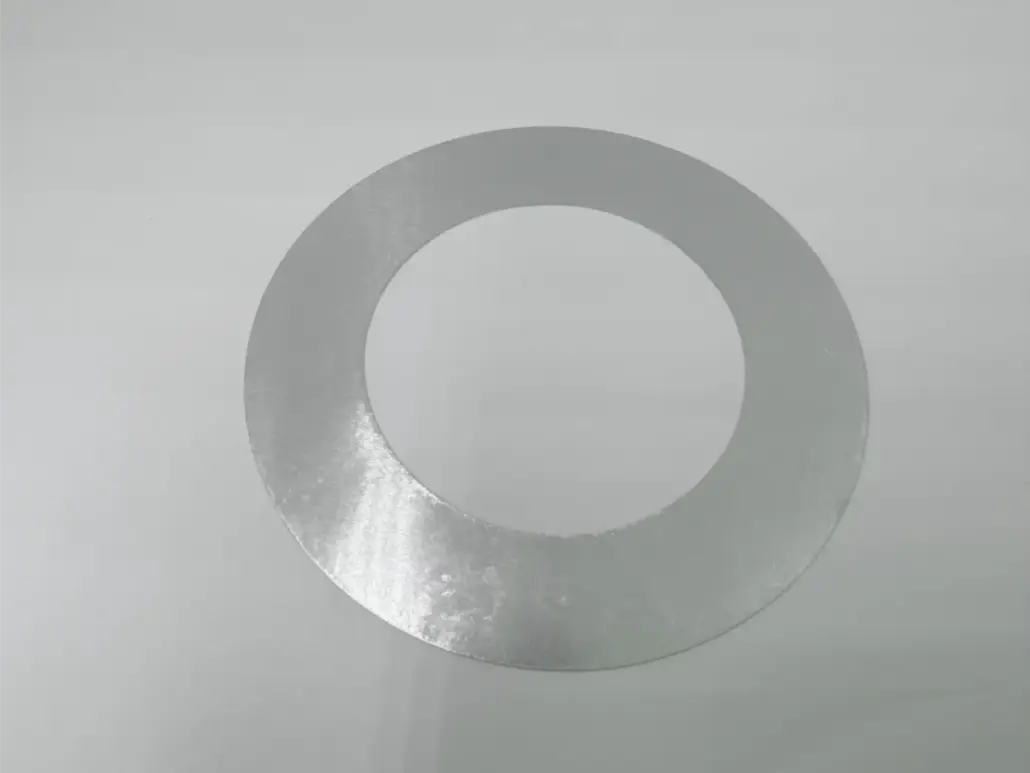

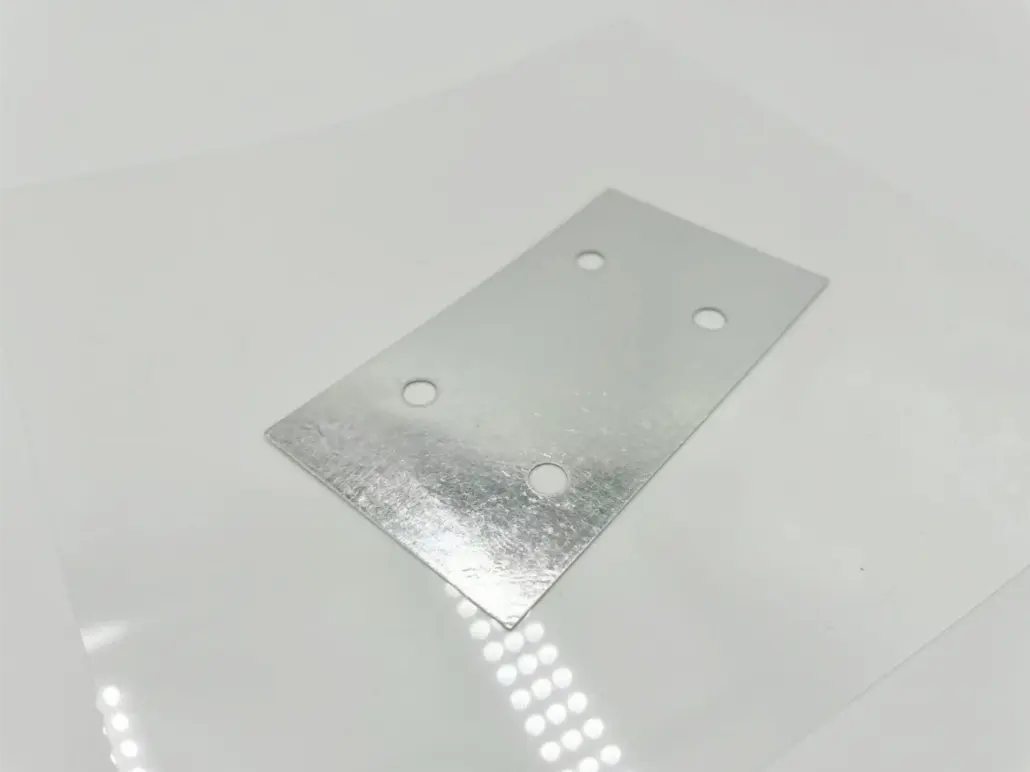

Indium seals are critical components used in a variety of industrial and technological applications that require reliable performance at low temperatures and moderate pressures. These seals leverage the unique properties of indium, a post-transition metal discovered in 1863, which is highly ductile, malleable, and capable of forming hermetic bonds without the need for heat. Historical…

The indium wire vacuum seal is a crucial component in the electronics manufacturing industry, ensuring the integrity and functionality of various devices. What is indium wire vacuum seal used for in electronics? Indium wire vacuum seal is a specialized sealant made from indium, a metal known for its soft, ductile nature and excellent thermal and…

As the demand for more efficient and reliable sealing solutions continues to grow, indium seal design is poised to play a crucial role in meeting these needs. In this article, we will explore some of the key innovations and trends that are shaping the future of indium seal design. One of the most significant trends…

Indium seals play a crucial role in ensuring the reliability and durability of various industrial and mechanical systems. These seals are made from indium, a soft, malleable metal that is known for its excellent thermal and electrical conductivity. Indium seals are commonly used in applications where high-temperature resistance and low outgassing properties are required. In…

The indium seal design has undergone significant evolution over the years, driven by the need for improved performance, reliability, and efficiency in various applications. This comprehensive overview will delve into the history of indium seal design, its current state, and the future trends that are shaping its development. Indium, a soft, low-melting-point metal, has been…

Basic Information of Indium Wire Indium wire, a unique and versatile material, has gained significant attention in recent years due to its remarkable properties and applications. In this article, we will delve into the science behind indium wire, exploring its composition, properties, and uses. Indium, a chemical element with the symbol In and atomic number…