Contact Us

If you have a question or would like to be contacted by one of our team, please complete the form below.We value your questions, comments and suggestions, looking forward to hearing from you!

A: With over a decade of experience in manufacturing Indium Foil, we boast a distinguished reputation for excellence, supported by our stringent quality control system and a dedicated research team.

A: We usually quote within 2 hours during our business work day. If you are in urgent need of a price, please call us or let us know by email so that we will give priority to your inquiry.

A: Delivery typically occurs within 5-7 business days via express couriers such as DHL, UPS, TNT, and FedEx, while shipments by sea usually take approximately 25-35 business days to reach the destination port.

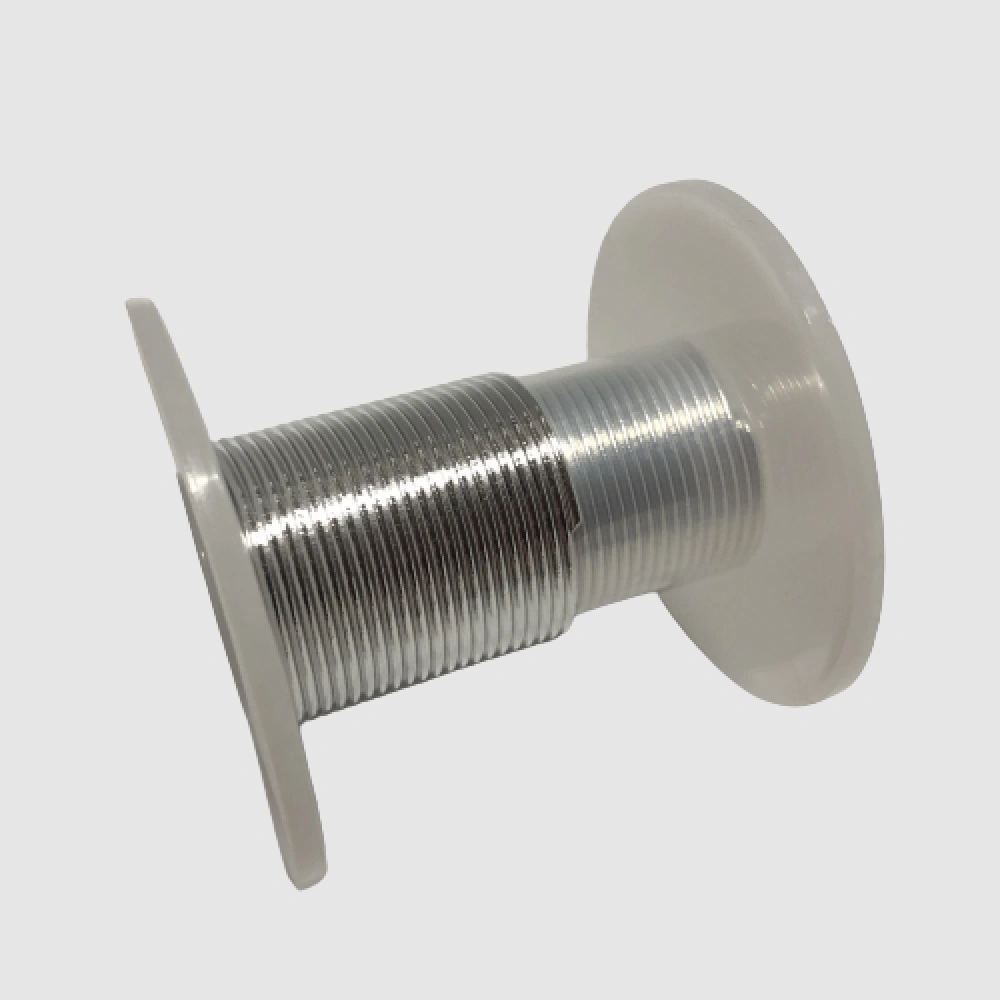

Aster offers Indium Solder Wire with diameters ranging from 0.1mm to 6mm, typically boasting purities of 99.995% and 99.999%. Additionally, we specialize in crafting various Indium Alloy wires such as Indium Lead Alloy Wire, Indium Bismuth Alloy Wire, and Indium Tin Alloy Wire, among others. Introducing additional elements alters properties like melting point, hardness, and malleability. We tailor Indium Wire and Indium Alloy Wire to your specifications. Each order is accompanied by a Certificate of Conformity and a Quality Analysis Certificate.

Product Details

| Product Name | INDIUM WIRE |

|---|---|

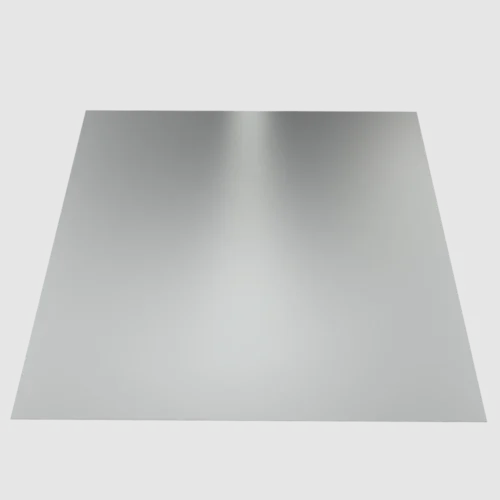

| Appearance | Silver-white metal |

| Size/ Weight | 500g/roll |

| Molecular Formula | In |

| Molecular Weight | 8.37 mΩ cm |

| Melting Point | 156.61℃ |

| Boiling Point | 2060℃ |

| CAS No. | 7440-74-6 |

| EINECS No. | 231-180-0 |

Indium Solder Wire Properties

- Low Melting Point: Indium solder wire has a relatively low melting point compared to traditional solders, making it ideal for delicate components that cannot withstand high temperatures.

- Excellent Wettability: It can wet many surfaces that other solders cannot, including glass, ceramics, and certain metals.

- High Thermal Conductivity: Indium’s excellent thermal conductivity is beneficial for applications requiring efficient heat dissipation.

- Electrical Conductivity: It provides good electrical conductivity, making it suitable for electronic applications.

- Ductility and Malleability: Indium solder is known for its softness and flexibility, which allows it to form robust seals without becoming brittle.

Indium Soldering Wire Diameter

The minimum diameter for Indium Wire is 0.3mm, while the maximum is 6mm. Our tolerance for diameter is ±0.01mm. Before you send inquiry to us, please tell us the diameter and length or the weight you might need. Should you have specific requirements, feel free to email our team for further discussion.

| Item No | Elements | Diameter | Length |

| Indium Wire | In | 0.3-6mm or up | 1m 2m 3m 5m 10m or as required |

| Indium Tin Wire | InSn | 0.5-6mm or up | 1m 2m 3m 5m 10m or as required |

| Indium Lead Wire | InPb | 0.5-6mm or up | 1m 2m 3m 5m 10m or as required |

| Indium Silver Wire | InAg | 0.5-6mm or up | 1m 2m 3m 5m 10m or as required |

Indium Wire Vacuum Seal Applications

- Channel sealing, hand sealing, Indium is soft enough to fill the gap between the two metal surfaces of the mating, forming a complete seal.

- Ultra-low temperature sealing materials, when temperature -150°C , Indium retains ductility and malleable property.

- Welding or fusion.

- High-end device cooling.

- Soldering and Brazing: Due to its low melting point and excellent wetting properties, indium wire is widely used in soldering and brazing applications. It is especially useful in electronics assembly and semiconductor manufacturing where delicate components require precise bonding.

- Sealing and Hermetic Packaging: Indium wire seal can create hermetic seals in vacuum and gas-tight enclosures. It is commonly used in the aerospace, automotive, and electronics industries to protect sensors, connectors, and optical devices from environmental contaminants.

- Thermal Interface Materials (TIMs): Indium wire is an effective thermal interface material, facilitating efficient heat transfer between components. It is used in CPUs, power electronics, and LED lighting systems to prevent overheating by dissipating heat.

- Thin-Film Deposition: Indium wire serves as a source material in thin-film deposition techniques like thermal evaporation and sputtering. These processes are used to produce indium-based thin films for electronics, optics, and photovoltaic applications.

- Semiconductor Industry: Indium solder wire is widely used in the semiconductor industry for attaching components and ensuring reliable electrical connections. It is particularly useful in sealing infrared detectors and other heat-sensitive devices due to its low melting point and high conductivity.

- Medical Devices: Precision soldering for medical devices often uses indium solder wire due to its reliability and quality, ensuring long-lasting and safe medical equipment.

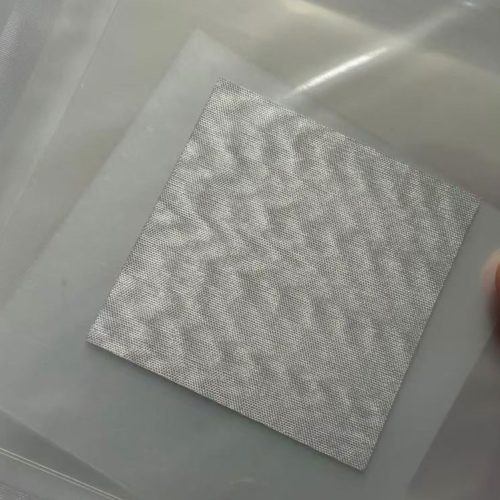

Packing, Transportation and Storage

Packing: Indium wire is packaged with wire spools, then vacuum bag in plastic container, 5meter/ roll or 250g/roll.

Transportation: By Fedex, DHL, UPS with door to door delivery, By Air

Storage: For optimal storage and to reduce surface oxidation, it’s essential to securely seal the indium wire in its original container. Maintain a relative humidity of 55% or lower and a temperature below 22°C. Alternatively, indium wire can be stored in an inert atmosphere, such as a nitrogen drying oven.

Technical and Customer Support

Our engineers boast extensive service expertise and offer comprehensive technical assistance to customers. They possess a profound understanding of indium wires and are well-versed in the applications of related materials within the electronics and semiconductor sectors.

To Globally Delivery High Quality Indium Foil-Thermal Interface Materials

About our factory

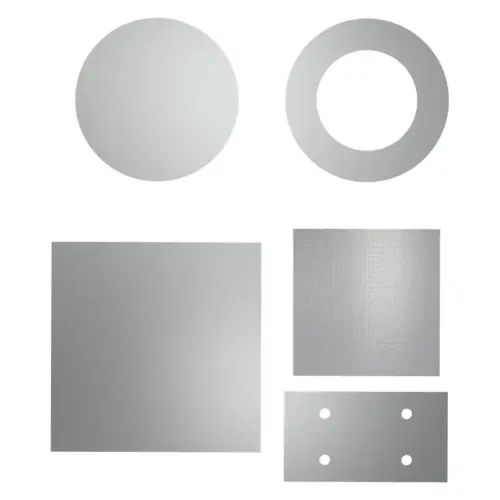

As one of the leading producer in re-processing Indium Elements materials, Aster uses it’s technological expertise to R&D and produce Indium Wire, Indium Foil, Indium Gasket, Indium Seal and customize all the different size of foils, Gasket, Seal, Sheet, ribbon etc..We will continue to supply high quality products and service to support our customers with competitive market rates.

Learn moreOUR EXHIBITION IN GERMANY, USA KOREAN AND JAPAN.

GET IN TOUCH WITH US

Give us a call

General Info: +86 18673173361

Technical Support: +86 17267477981

Online Chat

WHATSAPP-CLICK GREEN BUTTON

Indium Wire

A: With over a decade of experience in manufacturing Indium Foil, we boast a distinguished reputation for excellence, supported by our stringent quality control system and a dedicated research team.

A: We usually quote within 2 hours during our business work day. If you are in urgent need of a price, please call us or let us know by email so that we will give priority to your inquiry.

A: Delivery typically occurs within 5-7 business days via express couriers such as DHL, UPS, TNT, and FedEx, while shipments by sea usually take approximately 25-35 business days to reach the destination port.

Contact Us

If you have a question or would like to be contacted by one of our team, please complete the form below.We value your questions, comments and suggestions, looking forward to hearing from you!