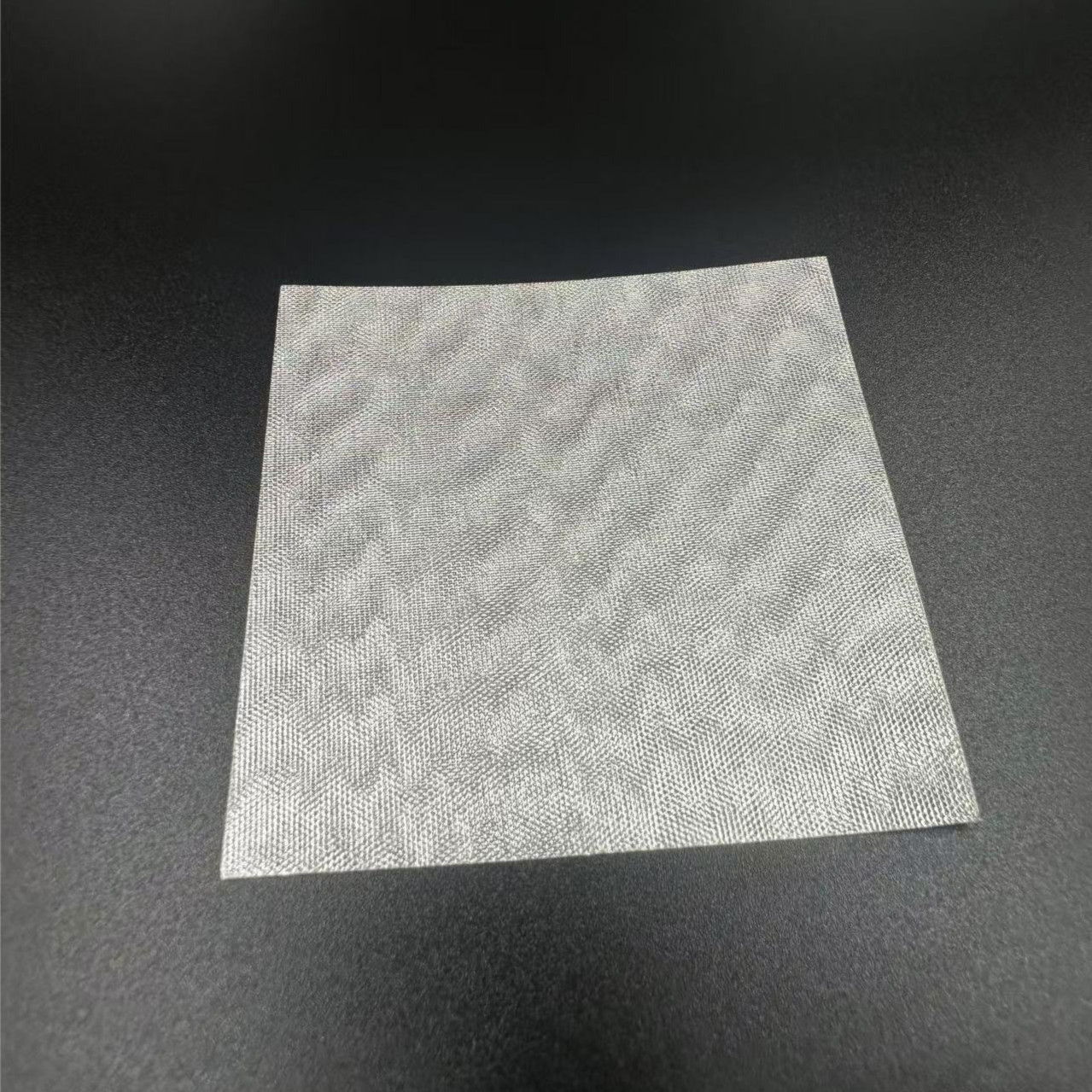

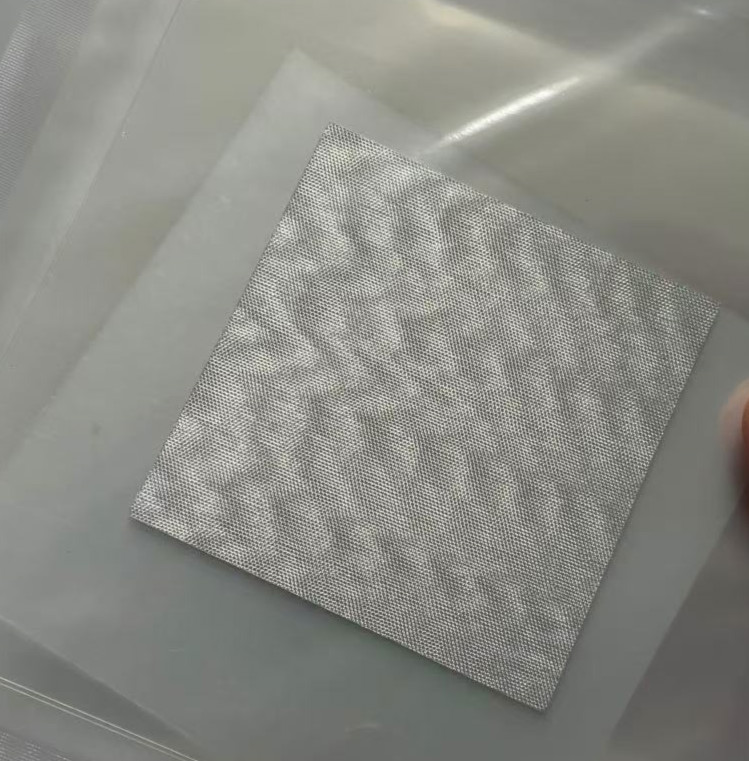

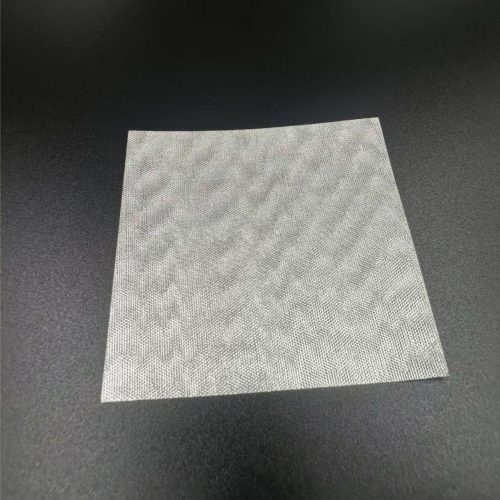

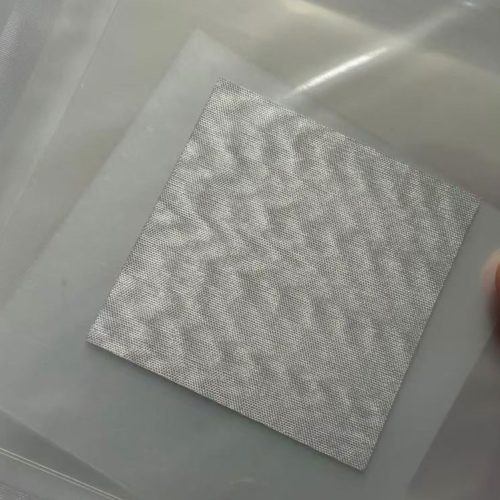

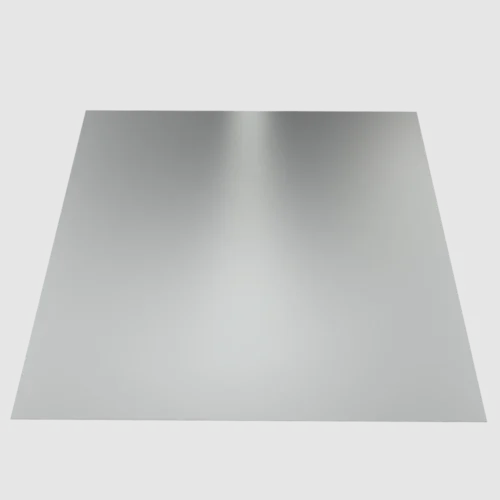

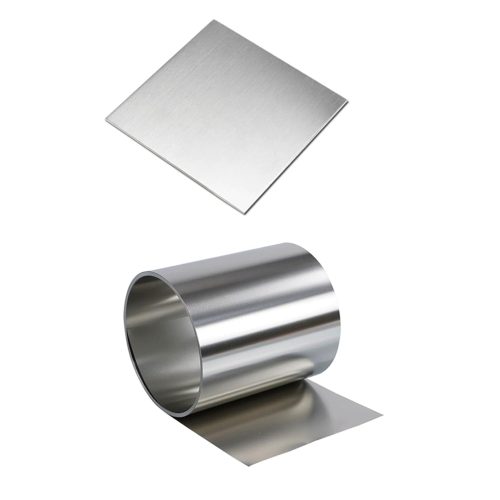

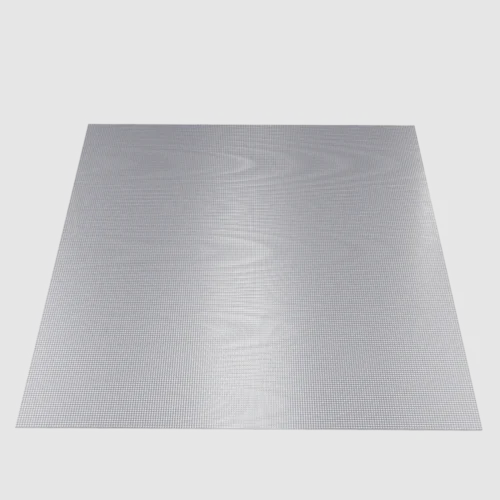

Patterned indium foil refers to indium foil that has been processed to include specific patterns or textures on its surface. These patterns are typically created through precision manufacturing techniques such as stamping, embossing, or etching. The primary purpose of patterned indium foil is to enhance its performance in specific applications, particularly those involving thermal management or sealing.

Key Features and Benefits:

- Improved Thermal Contact:

- The patterns increase the surface area, improving the thermal interface between the indium foil and the adjoining materials (e.g., heat sinks or substrates).

- This enhances heat transfer efficiency.

- Reduced Bonding Pressure:

- The textured surface allows for better compliance and adaptability to uneven surfaces, reducing the pressure needed to achieve a secure thermal or physical connection.

- Enhanced Sealing:

- For sealing applications, the patterns help distribute forces evenly, creating a more effective seal against leaks in vacuum or cryogenic environments.

- Application-Specific Customization:

- Patterns can be tailored for particular use cases, such as channels for heat dissipation or grooves to accommodate specific assembly requirements.

Applications:

- Thermal Interface Materials (TIMs): Used to bridge heat sources and heat sinks with enhanced thermal conductivity.

- Cryogenic Seals: Patterned indium foil is often used in cryogenic systems due to its ductility and ability to form airtight seals.

- Electronics and Optoelectronics: Provides thermal and electrical pathways for high-performance components.

By incorporating patterns, indium foil becomes more versatile and effective in high-demand scenarios, particularly in industries like aerospace, electronics, and advanced manufacturing.

Product Details

| Product Name | PATTERNED INDIUM FOIL |

|---|---|

| Appearance | Silver White |

| Molecular Weight | 114.82 |

| Density | 7.31 g/cm3 |

| Thermal Conductivity | 86 W/(m·K) |

| Melting Point | 156.61℃ |

| Boiling Point | 2060℃ |

| Resistivity | 8.37 μΩ-cm |

| Tensile Strength | 270 Psi |

Customization Services

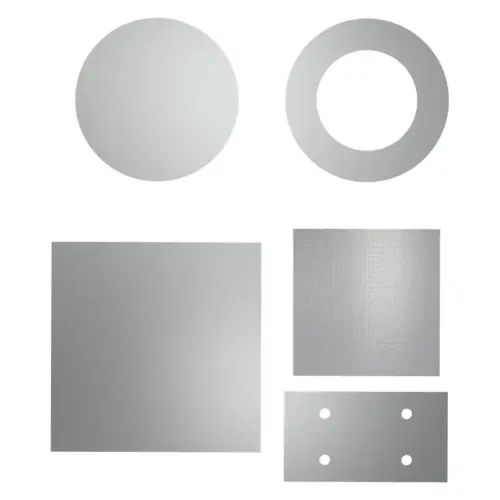

We offering customized services for Precut Indium Foil and Indium Sheet, the size range as belows:

Thickness Range: 0.05mm to 6mm

Width Range: 5mm to 200mm

Length Range: 5mm to 1000mm

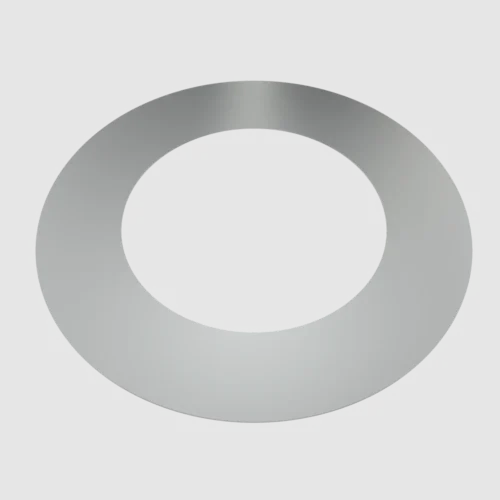

Patterned Choice: Single Side or Double side

We offer customization tailored to customer specifications or drawings. Additionally, we can craft indium foils in various shapes, such as holed, special-shaped, ring-shaped, and round, among others. If you have the demand for Indium Alloy Foil, you can send us your requests then our technical team will contact you for the possibility.

You can find the typical size of Indium foil, indium sheet, indium pad as belows, 50x50mm, 100x100mm, 150x150mm are the common used sizes, if you couldnot find the size you want, we can custom for you for even one piece, you can reach out to our engineer team for details.

| Product | Thickness | Dimension | Purity | MOQ |

| AM-IF-0050

Indium Foil |

0.05mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IF-0010

Indium Foil |

0.01mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IF-0100

Indium Foil |

0.1mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IF-0125

Indium Foil |

0.125mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IF-0500

Indium Foil |

0.5mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IS-1000

Indium Sheet |

1.0mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-IS-2000

Indium Sheet |

2.0mm | 10x10mm, 100x100mm, 150x150mm | 99.995% 99.999% | 1pc |

| AM-CM

Indium Foil |

0.05-6mm | Max Length 1000mm

Max Width 200mm |

99.995% 99.999% | 1pc |

| Generation 2.0

Indium Foil |

0.05-6mm | Max Length 1000mm

Max Width 200mm |

99.995% 99.999% | 1pc |

You will get 100% refund or free replacement if any quality problem.

5 Steps to Get Custom Indium Foils

- Step 1: Click the “Order Now” button or visit the “Contact Us” page to submit your request. You can also find our email address in the “Get in Touch” section.

- Step 2: Provide details such as purity, size, quantity, and shipping address. For custom sizes, attach a drawing for technical support.

- Step 3: Submit your inquiry. Our sales or technical team will respond within 1-2 hours.

- Step 4: Confirm your requirements. We will send you an invoice for payment.

- Step 5: After payment, production begins. Once quality checks are done, we’ll pack your order and send tracking details along with the documents. Confirm receipt.

To Globally Delivery High Quality Indium Foil-Thermal Interface Materials

About our factory

As one of the leading producer in re-processing Indium materials, Aster uses it’s technological expertise to R&D and produce a range of Indium products, including Indium Foil, Indium Alloy Foil, Indium Wire, and Indium Seal. Our Indium products exported to more than 50 countries worldwide. Strategically situated in Changsha, Hunan, a major production area for Indium mines and products in the world. we are dedicated to delivering high-quality Indium products and services to support our business partners worldwide.

Learn moreOUR EXHIBITION IN GERMANY, USA KOREAN AND JAPAN.

Get in Touch

Give us a call

General Information: +86 18673173361

Technical Support: +86 17267477981

Patterned Indium Foil

A: With over a decade of experience in manufacturing Indium Foil, we boast a distinguished reputation for excellence, supported by our stringent quality control system and a dedicated research team.

A: We usually quote within 2 hours during our business work day. If you are in urgent need of a price, please call us or let us know by email so that we will give priority to your inquiry.

A: Delivery typically occurs within 5-7 business days via express couriers such as DHL, UPS, TNT, and FedEx, while shipments by sea usually take approximately 25-35 business days to reach the destination port.

Contact Us

If you have a question or would like to be contacted by one of our team, please complete the form below.We value your questions, comments and suggestions, looking forward to hearing from you!