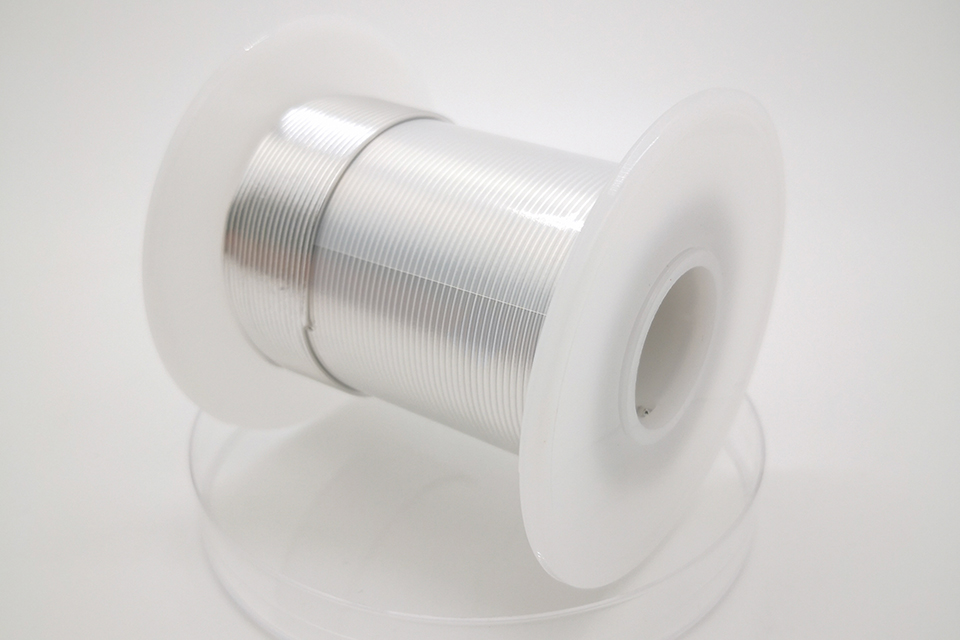

Exploring the Versatility of Indium Wire Indium wire, a versatile and highly conductive material, has found its way into a multitude of applications across various industries. Its unique properties make it an ideal choice for a wide range of purposes, from electronics to medical devices. In this article, we will delve into the world of…

Achieving optimal hermetic sealing with indium seals requires meticulous attention to various factors. Factors Influencing Indium Seal Hermeticity Indium seals are crucial in achieving hermetic sealing across various applications, including vacuum tubes, sensors, and electronic devices. The effectiveness of these seals hinges on several critical factors: Purity of Indium Material: The purity of indium significantly…

Indium seal possesses distinctive properties that make it highly effective for creating hermetic seals: Surface Adhesion and Bonding Strength Indium’s low surface tension and high surface energy enable it to form robust bonds with various materials. This capability ensures tight adhesion, creating a seamless barrier against gases and liquids. Solid-State Transformations Indium undergoes solid-state transformations:…

Choosing between an Indium seal and an Indium Silver seal depends on specific requirements. Here are some considerations: Physical Properties Solder Alloy 97In3Ag by wt% 90In10Ag by wt% 100% Indium Solidus (°C) 143 143 156 Liquidus (°C) 143 237 156 Density (gm/cm3) 7.38 7.54 7.31 Tensile Strength (psi) 1330 1364 386 Thermal Conductivity (W/m⋅K) 75 71 86 Electrical Conductivity (µΩ⋅m)…

Indium exhibits self-passivating properties. At typical room temperature, a thin oxide layer forms on the surface of indium Wire or Indium Foil, measuring between 80-100 Angstroms thick.Typically, this oxide layer is not substantial enough to impede the wetting of indium onto a substrate, particularly when flux is applied. However, even in the absence of flux,…

Creating an indium wire seal involves using indium wire to seal joints or gaps between two surfaces. Here’s how you can make an indium wire seal: Materials Needed: Indium wire (99.995%, 99.999%) Surfaces to be sealed (e.g., glass, metal) Clean cloth or alcohol wipes Heat source (e.g., soldering iron) Flux (optional, for better adhesion) Steps:…

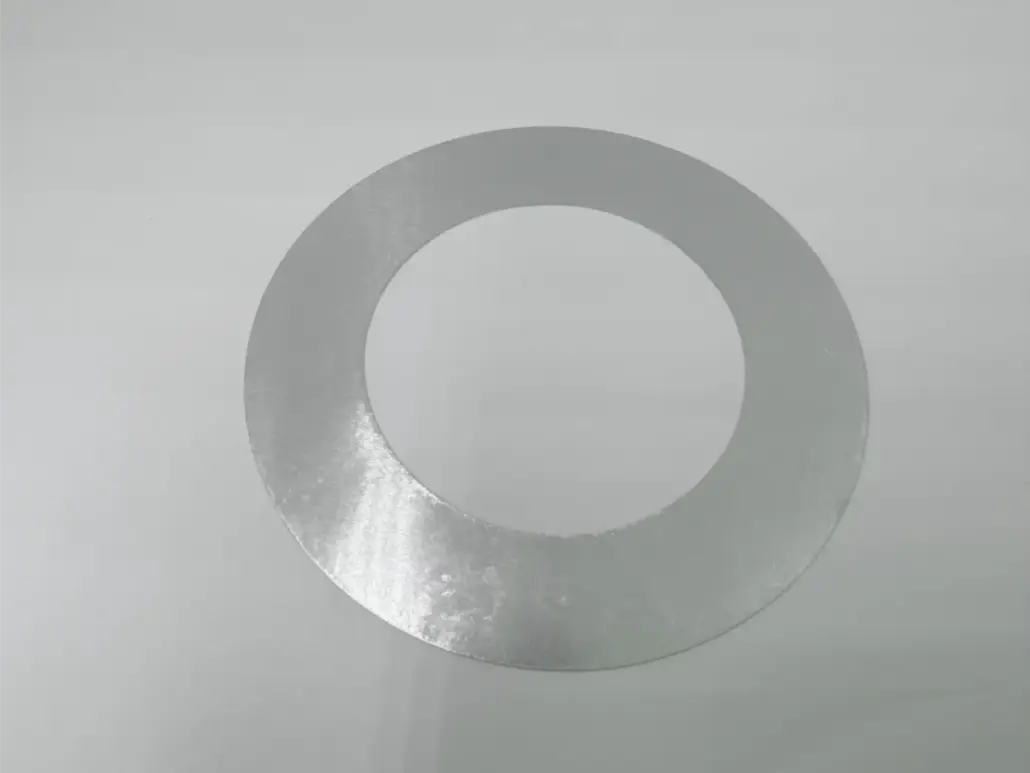

An indium O-ring is a type of sealing ring or gasket primarily made from indium or an indium-based alloy. O-rings are circular elastomeric seals with a round cross-section, designed to be placed in a groove and compressed between two or more parts to create a seal. Indium O-rings have specific properties that make them suitable…

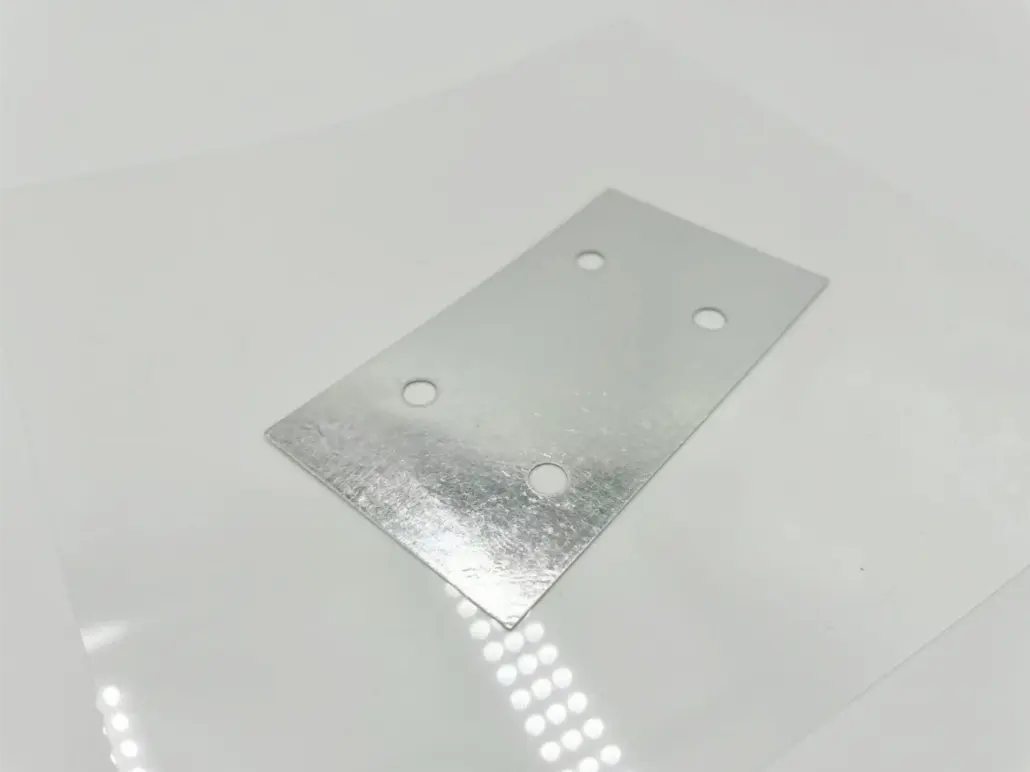

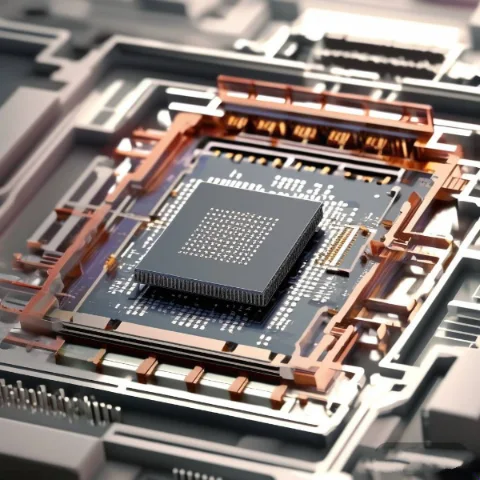

Indium foil cooling thermal pads are used in electronics and other high-performance cooling applications to improve thermal conductivity between components. Indium is a metal with excellent thermal and electrical conductivity, making it an ideal material for thermal interface pads. These pads are often used to enhance the heat dissipation from components like CPUs, GPUs, power…

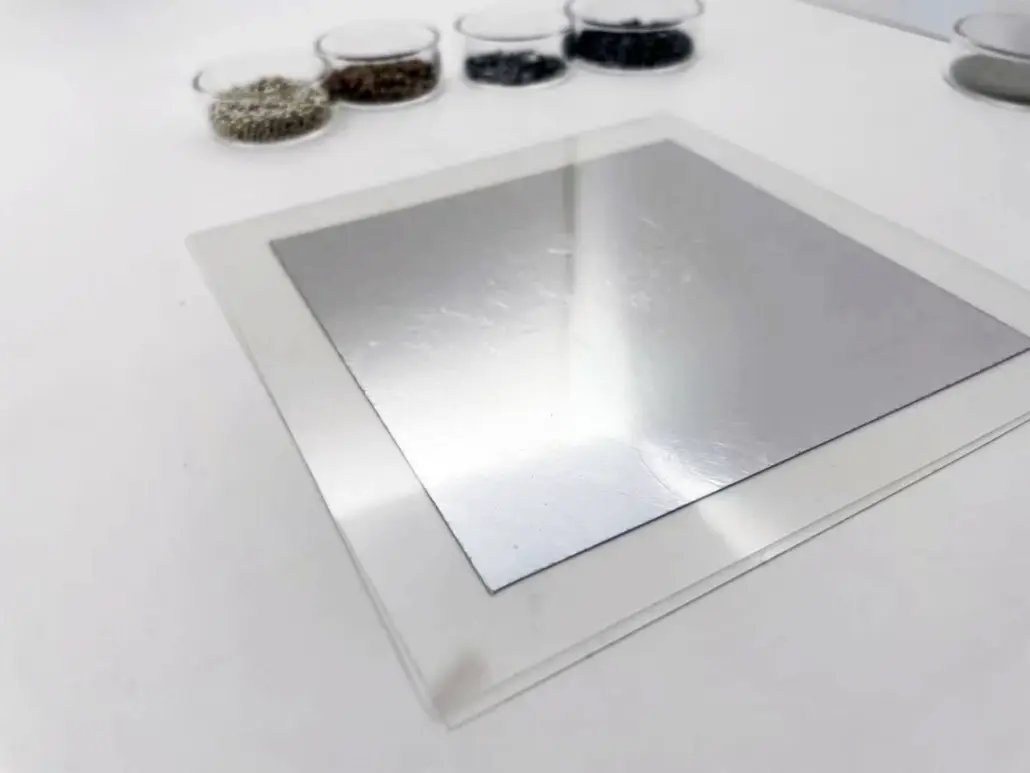

Indium sheets play a crucial role in semiconductor sealing processes, primarily used to enhance the thermal and electrical performance and reliability of devices. Indium is a silvery-white metal with excellent plasticity and a low melting point (approximately 156.6 degrees Celsius), making it particularly useful in semiconductor packaging. Here are the applications and processes of indium…

Indium foil is used in semiconductor sealing to leverage its unique physical and chemical properties, improving the overall performance of the sealing. Here are the key benefits: Excellent Thermal Conductivity: Indium foil’s high thermal conductivity significantly enhances the heat dissipation efficiency of semiconductor devices. During packaging, it serves as a thermal interface material, effectively transferring…