Indium Vacuum Seal stands out as a superior material for creating helium-tight hermetic seals, bridging metals and non-metallic substrates like glass and ceramics. Its versatility extends to cryogenic environments, vacuum pumps, and heat-sensitive areas, where it ensures reliable containment.

When indium serves as the sealant, it initiates a chemical bond with the surfaces it connects, distinct from the mere barrier formation of other gasket materials. Notably, indium seals demonstrate resilience against mechanical shock, vibration, and extreme temperatures, making them indispensable in demanding applications.

An inherent property of indium is its tendency to develop an oxide film on its surface. To establish a pristine bond with a substrate, this film must be disrupted through compression and plastic deformation. This process, facilitated by the malleability of indium, occurs readily even at cryogenic temperatures, ensuring effective sealing.

The quality of an indium seal hinges upon several factors:

- Purity and cleanliness: Optimal Indium purity levels of 99.99% are preferred, though select applications demand 99.999% Indium purity. Contaminants, especially organic compounds, should be removed through degreasing. Surface oxides can be eliminated with a brief dip in 50% hydrochloric acid, followed by rinsing in deionized water.

- Surface preparation: All surfaces must undergo thorough cleaning and drying. Glass and ceramic surfaces require treatment with chromic and sulfuric acids, followed by hydrochloric acid and deionized water rinse. Indium Metal surfaces may be bare, pre-tinned with indium, or plated with indium or silver. Surface finishing should be carefully executed, without over-polishing or abrasive alteration.

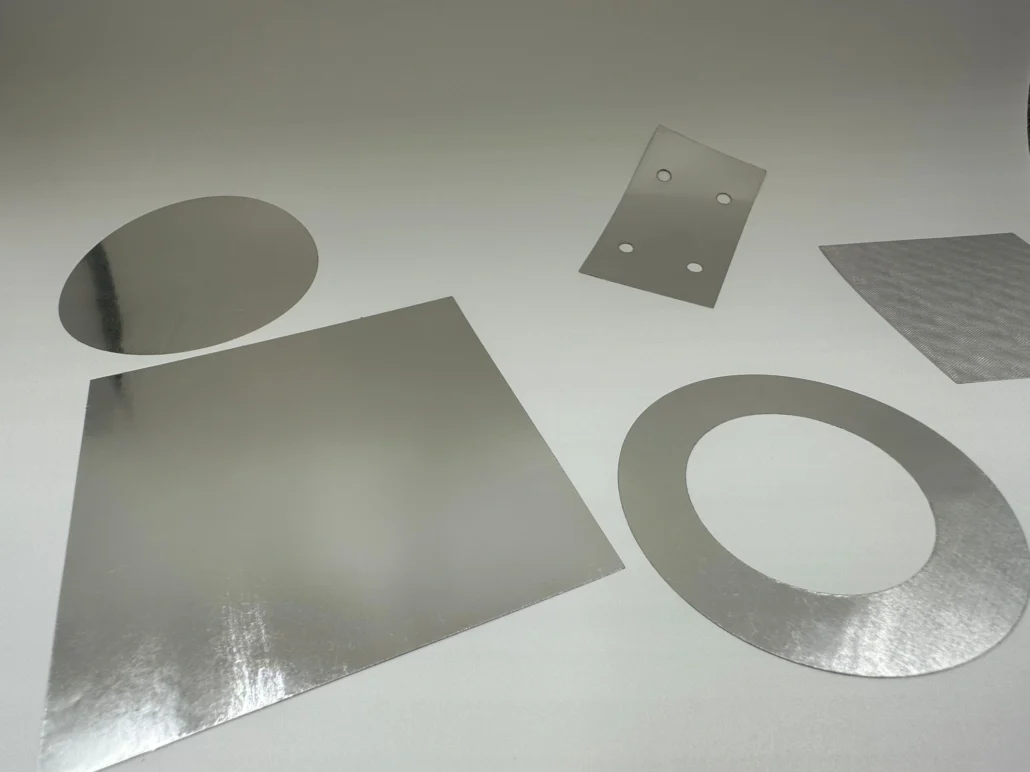

- Thickness and shape of indium: Indium Seal thickness varies based on surface area and compressive force. Indium ‘O’ ring groove applications, the Indium seal should exceed the groove’s dimensions by 5-15% when compressed. Overlapping segments of indium can substitute for a continuous washer in certain scenarios. Well-formed seals exhibit leak rates below 2 x 10-7 torr x liter/sec.

By adhering to meticulous procedures for indium selection, surface preparation, and seal configuration, engineers can ensure the reliability and effectiveness of hermetic seals in critical applications.

Physical Properties

One of the most notable physical properties of indium is its exceptional ductility and malleability. Indium possesses a Mohs hardness of just 1.2, significantly lower than that of copper (2.5-3) and aluminum (2-2.9), making it much softer and easier to deform.

It has a relatively low melting point of 156.6°C, allowing it to be easily molded into various shapes and sizes, such as preforms and wires, to fit specific sealing applications.

Indium can be fabricated into thicknesses ranging from thin (0.008 inches) to thick (0.062 inches), depending on the mating surfaces and required compressive forces.

Chemical Properties

Sealing Characteristics

Indium‘s ability to form hermetic seals without the need for heat is particularly advantageous in environments where heat or solder flux might cause issues such as outgassing.

When used as a sealant, indium initiates a chemical bond with the surfaces it connects, offering superior sealing capabilities compared to other gasket materials which merely act as barriers.

This property allows indium seals to maintain their integrity even under mechanical shock, vibration, and extreme temperatures, making them indispensable in demanding applications.

Surface Preparation

Proper surface preparation is critical for achieving high-quality indium seals. Surfaces must be thoroughly cleaned and dried, with specific treatments for different materials. For example, glass and ceramic surfaces should be treated with chromic and sulfuric acids, followed by a hydrochloric acid and deionized water rinse.

Indium metal surfaces may require pre-tinning or plating with indium or silver to ensure optimal bonding.

The removal of surface oxides through compression and plastic deformation is facilitated by the malleability of indium, ensuring effective sealing even at cryogenic temperatures.

Indium’s versatility extends to its use in forming helium-tight hermetic seals, capable of bridging metals and non-metallic substrates like glass and ceramics. This makes indium an essential material in applications requiring reliable performance in vacuum pumps, cryogenic environments, and other heat-sensitive areas.

Indium Vacuum Sealing Technology

Indium vacuum sealing technology leverages the unique properties of indium to create reliable and effective seals in a variety of applications, including cryogenic environments, vacuum pumps, and heat-sensitive areas.

This technology is particularly valued for its ability to form helium-tight hermetic seals, bridging both metallic and non-metallic substrates like glass and ceramics.

Properties and Advantages

Indium is characterized by its low melting point, high malleability, and ductility, which make it an ideal material for vacuum sealing.

Unlike gaskets made from other materials that only form a barrier, indium creates a chemical bond with the surfaces it connects, enhancing the seal’s resilience against mechanical shock, vibration, and low temperatures.

A notable feature of indium is its tendency to develop an oxide film on its surface. To establish a pristine bond with a substrate, this oxide film must be disrupted through compression and plastic deformation, a process facilitated by the metal’s malleability.

This ensures effective sealing even at cryogenic temperatures without the need for heat.

Applications

Indium vacuum seals have a wide array of applications due to their unique properties and ability to operate effectively under extreme conditions. The versatility of indium seals makes them suitable for industries ranging from aerospace and automotive to medical and industrial sectors.

Aerospace and Automotive

In the aerospace and automotive sectors, indium seals are used for their excellent sealing properties and their ability to maintain a vacuum under high-pressure and high-temperature conditions. This ensures the integrity of components and systems that operate in harsh environments.

Medical and Industrial

The medical and industrial applications of indium vacuum seals are extensive. Indium seals are used in medical devices and equipment that require high purity and reliability, such as diagnostic tools and bioimplants. For instance, personalized medicine and point of care (POC) diagnostics often rely on devices that operate at a molecular level, where the precise functioning of seals is crucial.

Smart Technology Integration

A growing trend in indium seal design is the integration of smart technology. With the expansion of the Internet of Things (IoT), there is an increasing demand for sealing solutions that can monitor and control various processes in real-time. Indium seals are well-suited for these applications due to their unique properties, allowing them to be used in a wide range of scenarios. By incorporating sensors and other smart devices into indium seals, manufacturers can create more efficient and intelligent sealing solutions.

Surface Analytical Techniques

In the realm of ultra-high vacuum (UHV) applications, indium seals are critical for maintaining the vacuum conditions necessary for surface analytical techniques. These techniques include X-ray photoelectron spectroscopy (XPS), Auger electron spectroscopy (AES), secondary ion mass spectrometry (SIMS), and others. UHV conditions are essential to reduce surface contamination during these analyses. Indium seals help achieve the stringent vacuum conditions required for these high-precision techniques, enabling accurate and reliable measurements.

Emerging Technologies

Emerging technologies such as anti-fouling properties, bioimplants, and diagnostic devices also benefit from the use of indium vacuum seals. These applications require a fundamental understanding of biointerfaces and the ability to maintain sterile and contaminant-free environments. Indium seals contribute significantly to these fields by providing reliable sealing solutions that meet the rigorous demands of modern technology.

Summary

An indium vacuum seal is a specialized sealing technology that leverages the unique properties of indium, a post-transition metal known for its malleability, ductility, and ability to form hermetic seals. Indium vacuum seals are highly valued for their ability to form helium-tight hermetic seals by chemically bonding with the surfaces they connect. This chemical bonding, as opposed to merely acting as a barrier, ensures superior sealing capabilities that withstand mechanical shock, vibration, and extreme temperatures.