Indium foil, a remarkable thermal interface material (TIM), offering superior heat dissipation for components like CPUs. Its efficient heat transfer enables smaller cooling systems, prolonging battery life. Moreover, its soft, ductile nature ensures better surface coverage, reducing airflow gaps and enhancing heat flow. Unlike paste or grease, this indium foil remains intact over time, maintaining its effectiveness without leaching or drying out. It’s user-friendly, requiring no surface prep and boasts corrosion resistance, eliminating the need for special storage.

Indium foil with 48% tin enhances tensile and shear strength compared to tin-free variants, but with lower thermal conductivity.

Widely embraced in the electronics industry, Indium foil serves in conductor and semiconductor heat dissipation, particularly as a highly efficient heat sink in extreme temperature conditions. It finds applications in solid-state lithium batteries, catalysis, and thermal neutrons capture.

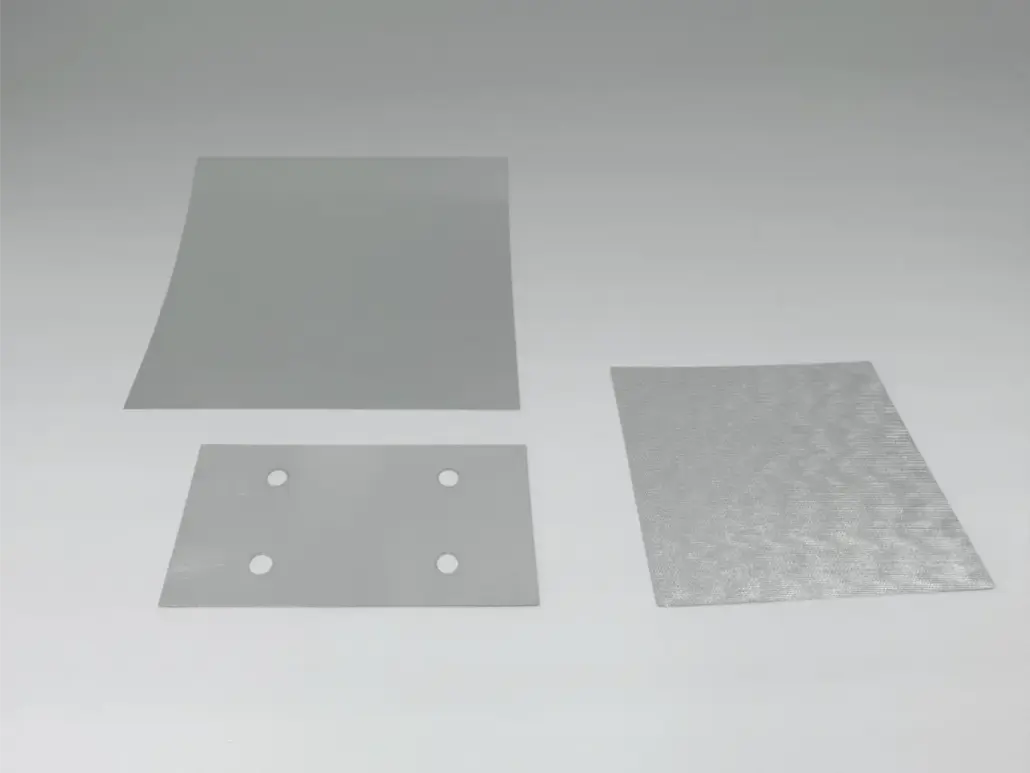

Customizable in size and thickness, Indium foil is available alongside high-purity ingots, rods, granules, pads, and wires. Crafted from pure Indium ingots, the foil offers exceptional thermal conductivity, crucial for demanding high-temperature and cryogenic environments. Our advanced production process ensures precise dimensions and purity, sealed within protective plastic sheets for secure transportation.

Pure Indium foils emerge as premium TIMs, boasting unrivaled thermal conductivity of 86 W/m-k, surpassing graphite sheets or thermal grease. These pads seamlessly fill microscopic gaps, ensuring consistent performance across a wide temperature range, from cryogenic to 156°C. Moreover, they offer mess-free disassembly and longevity, ideal for various industries and research applications.

Applications:

- Electronics: Indium foil finds widespread use in electronic components and soldering applications, enabling effective bonding with its low melting point.

- Aerospace: Leveraging its superior thermal and electrical conductivity, Indium foil is integral to aerospace components, spacecraft, and communication systems.

- Research: Indium foil’s chemical stability and low reactivity make it a staple in laboratory environments for diverse experiments and studies.

- Thin Films: Its precise dimensions and thin profile make Indium foil ideal for thin film deposition techniques like sputtering and evaporation.

- Solar Cells: Indium foils facilitates efficient energy transfer in solar cell production as a conductive layer.

- Medical Applications: Recognized for its biocompatibility, Indium foil is utilized in medical settings for dental fillings and implants, ensuring patient safety and comfort.

By exploring the versatile applications of Indium foil, industries and researchers can harness its unique properties to drive innovation and efficiency across various fields.

You can visit our website to find more detials.