Indium wire is a type of fine wire made of pure indium, typically characterized by high purity and good conductivity.

The Mohs hardness of metallic indium is only 1.2, much lower than the Mohs hardness of copper (2.5-3) and aluminum (2-2.9), with a melting point of 156.6°C. Its excellent ductility makes it very advantageous for vacuum sealing connections.

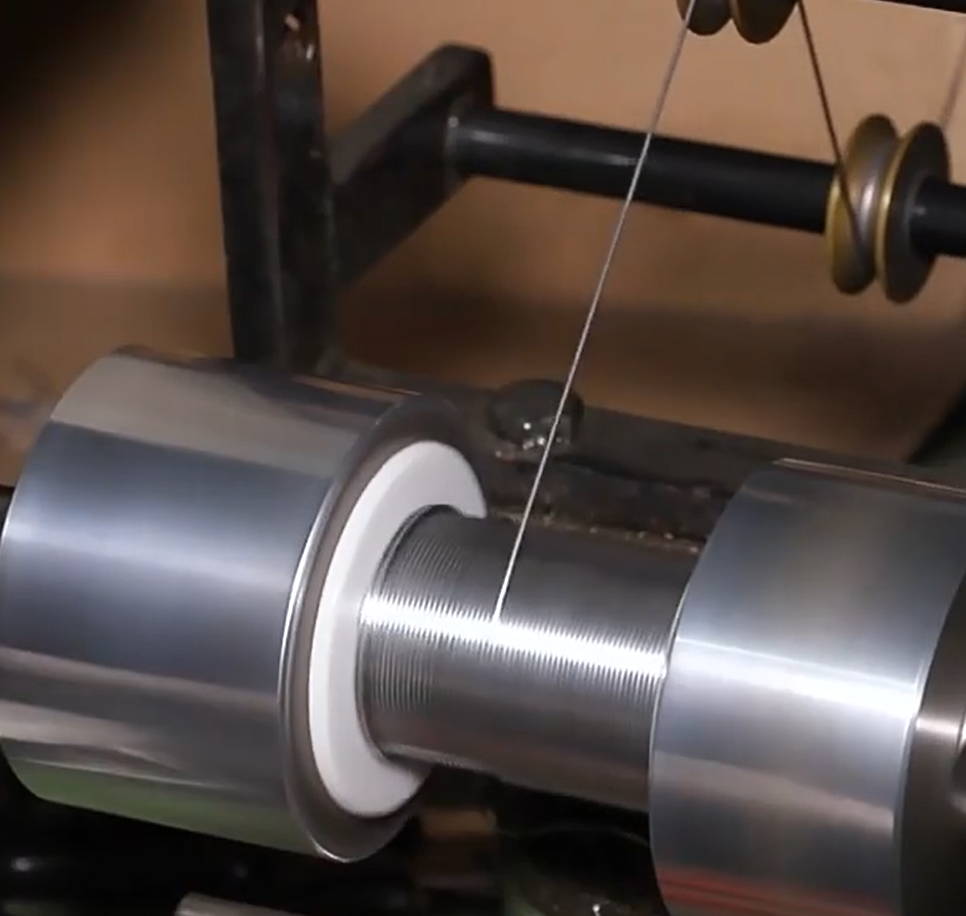

During sealing, a suitable length of indium wire is placed on the flange surface, and the ends of the indium wire are simply overlapped, eliminating the need for pre-processing into standard sealing rings. Therefore, it is often used in cases where flange sizes are large and other metal sealing rings are difficult to manufacture.

Depending on the size of the flange, the diameter of the indium wire can be selected within the range of 1 to 2 mm. However, due to its low melting point, the baking temperature should not exceed 150°C. Furthermore, metallic indium exhibits excellent low-temperature performance, making indium wire seals commonly used in low-temperature vacuum sealing environments.

However, indium wire is prone to flow after being compressed, so flanges need to be designed with steps or grooves, to prevent the indium wire from flowing into the vacuum chamber.

Explore the benefits of indium wire seals for your vacuum sealing needs, feel free to contact us if you have any questions about the wire.