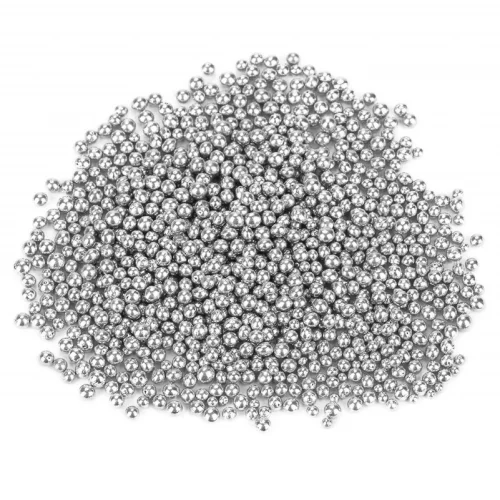

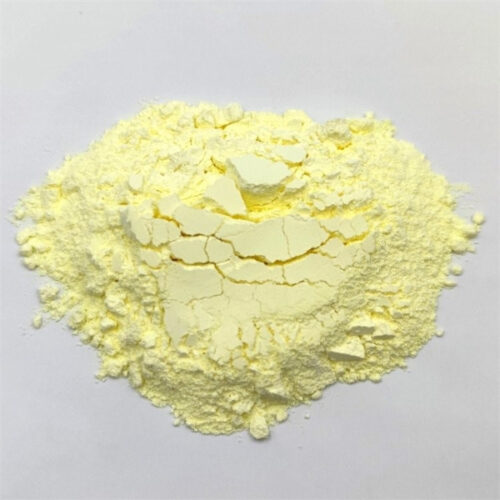

Indium tin oxide (ITO or tin-doped indium oxide) is a mixture of indium(III) oxide (In2O3) and tin(IV) oxide (SnO2), produced using special firing techniques. It is made of tin-doped indium oxide nanoparticles with a primary particle size of 40nm. By weight, it typically consists of 90% indium oxide (In2O3) and 10% tin oxide (SnO2), or 95% indium oxide and 5% tin oxide. Common colors are pale yellow and blue.

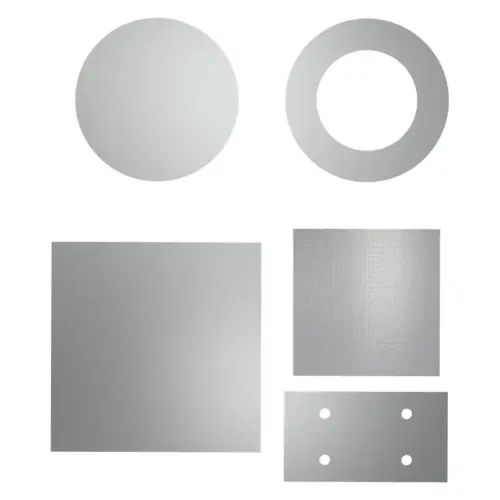

Powdered indium tin oxide (ITO) comes in two colors: pale yellow and blue. However, when deposited as a thin film with a thickness of 1000 – 3000 Angstroms, it becomes transparent. When deposited as a thin film on glass or transparent plastic, it functions as a transparent conductor.

ITO is mainly used in the production of LCD displays, flat panel displays, plasma displays, touch screens, electronic paper, organic light-emitting diodes (OLEDs), solar cells, anti-static coatings, EMI shielding transparent conductive coatings, and various optical coatings.

| Name | Nano Indium Tin Oxide, ITO Powder |

| Purity | 99.99% |

| Appearance | Light Yellow or Deep Blue Powder |

| Ratio | In2O3:SnO2 90:10 or 95:5 |

| Particle Size | 20-70nm |

Nano Indium Tin Oxide Feathers

- Excellent conductivity: The conductive coating made from this material can achieve a resistance as low as 80 Ω·cm.

- High transparency: The coating or thin film produced can achieve a transparency of over 90%.

- Strong weather resistance: Chemically stable and thermally stable, with no degradation in functionality over time.

- Good dispersibility: Easily disperses in water and other solvents, forming stable systems.

Nano ITO Powder's Applications

ITO is primarily used in the production of:

- LCD displays, Flat panel displays, Plasma displays, Touch screens, Electronic paper applications, Organic light-emitting diodes (OLEDs), Solar cells, Anti-static coatings, Transparent conductive coatings for EMI shielding.

- ITO is also used in various optical coatings, most notably: Infrared-reflective coatings (heat mirrors) in architecture, Automotive applications, Sodium vapor lamp glass.

- Other applications include: Gas sensors, Anti-reflective coatings, Bragg reflectors for VCSEL lasers.

- ITO thin film strain gauges can be used in harsh environments and at temperatures above 1400 °C, such as in: Gas turbines, Jet engines, Rocket engines.

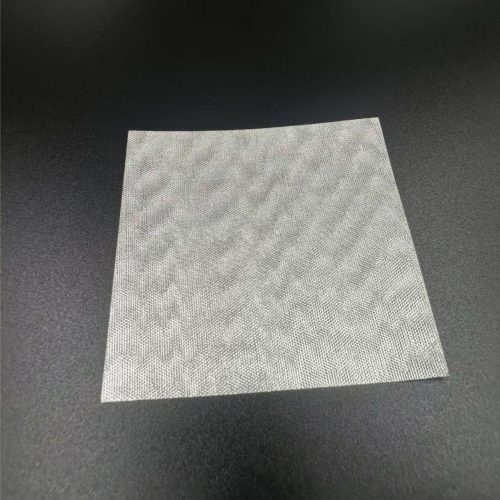

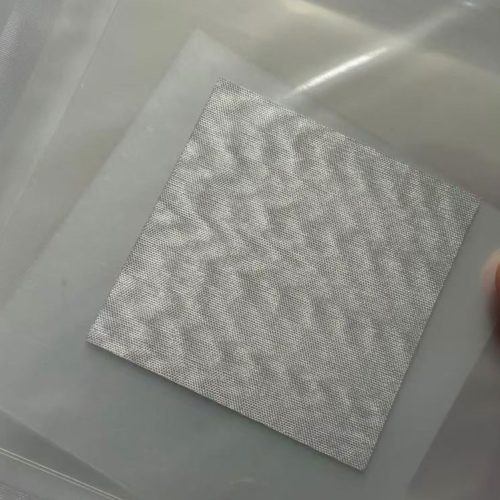

Blue Yellow ITO Packaging and Storage

The product is packaged in inert gas-filled anti-static bags or drums, or in vacuum-sealed bags. After receiving, it should be stored in a sealed container in a dry, cool environment. It should not be exposed to air for extended periods to prevent moisture absorption, which could lead to agglomeration and affect its dispersibility and performance.

Get in Touch

Give us a call

General Information: +86 18673173361

Technical Support: +86 17267477981