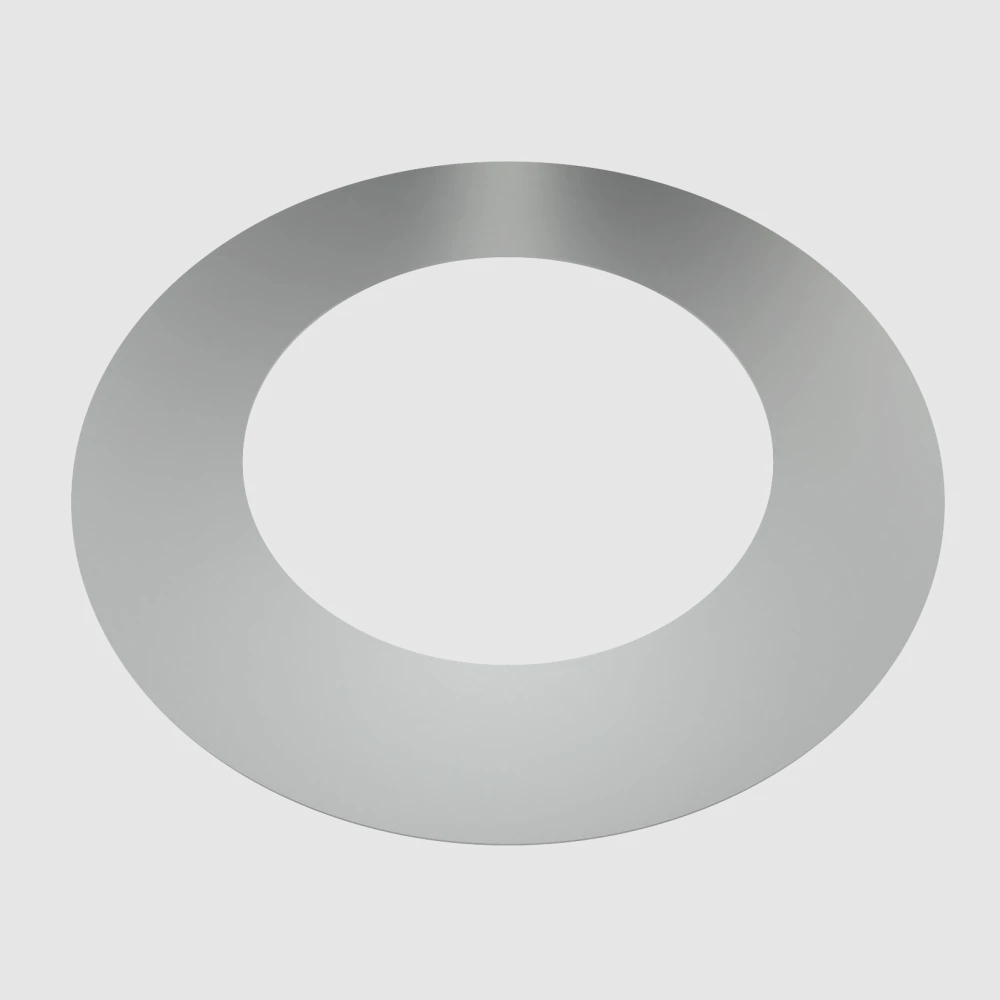

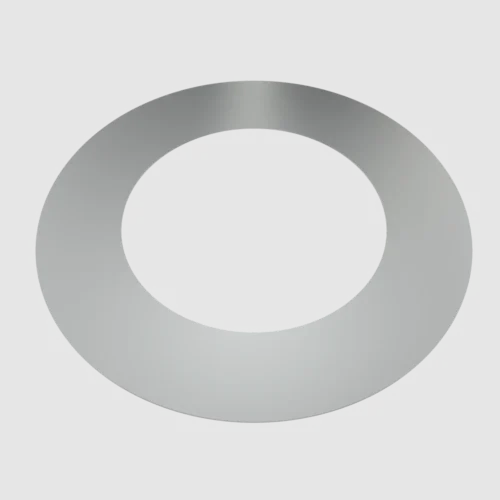

Indium seal serve as versatile gaskets for pressure and vacuum sealing needs. When applied between a silicon diode or temperature sensor and a refrigerator cold table, an indium gasket enhances thermal contact, preventing sensor detachment due to vibrations. Additionally, it proves effective for sealing covers, flanges, and windows in low-temperature environments. Its pliability persists even in low temperatures, making it an ideal choice for cryogenic pumps, high vacuum systems, and various specialized connection and sealing applications.

Properties of Indium Seal Gasket

- Ductility and Malleability: Indium sealing remains ductile and malleable even at cryogenic temperatures (below -150°C), which makes it an excellent material for seals that need to remain flexible under extreme conditions.

- Oxidation Resistance: Indium forms a very thin oxide layer (80-100Å) that protects the underlying metal from further oxidation, ensuring the longevity and reliability of the seal in various environments.

- Purity Levels: For high-quality seals, especially in critical applications like cryogenics, indium purity levels of 99.995% (4N5) to 99.999% (5N) are preferred. This high purity ensures minimal contamination and maximizes performance.

- Adhesion: Indium adheres well to a variety of materials, including metals like stainless steel, copper, and brass, as well as to glass. The adhesion mechanisms vary—mechanical locking for metals with surface imperfections and wetting action for smooth glass surfaces.

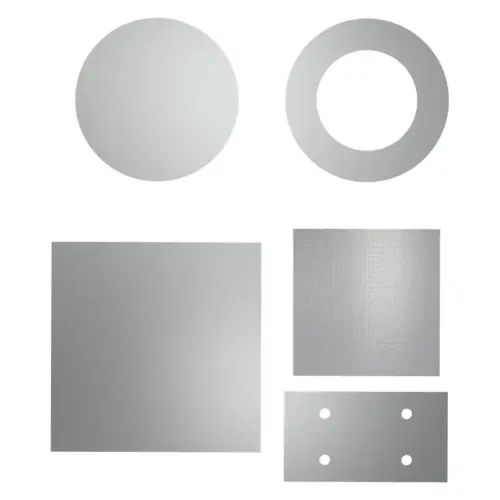

Customization Services

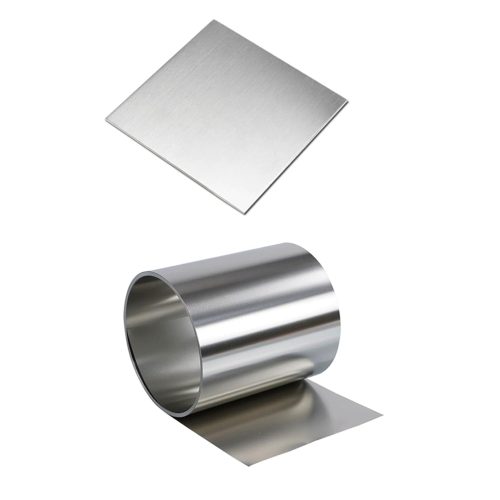

We offering customized services for Indium Seal and Indium Gasket, the size range as belows:

Thickness Range: 0.05mm to 6mm

Diameter:<200mm, Inner Diameter, Outer Diameter

Precut Holes or not: If you need holes on the Indium seal, you need provide drawing.

| Product | Thickness | Diameter | Purity | MOQ |

| AM-IS01-Indium Seal | 0.01mm | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS02-Indium Seal | 0.02mm | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS03-Indium Seal | 0.03mm | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS05-Indium Seal | 0.05mm | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS06-Indium Seal | 0.1 | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS07-Indium Seal | 0.2 | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS08-Indium Seal | 0.5 | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS09-Indium Seal | 1.0 | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| AM-IS10-Indium Seal | 1.5 | OD<200mm

ID<200mm |

99.99%

99.999% |

2PC |

| Custom Indium Seal | 0.01-6.0mm | Diameter<200mm | 99.99%

99.999% |

2PC |

| If you need precut holes on the indium washer, please send us the drawing. | ||||

We offer customization tailored to customer specifications or drawings. Additionally, we can craft indium seal design in various shapes, such as holed, special-shaped, ring-shaped, and round, among others. If you have the demand for Indium Alloy Seal, you can send us your requests then our technical team will contact you for further disscusion.

You will get 100% refund or free replacement if any quality problem.

5 Steps to Get Custom Indium Seals

- Step 1: Click the “Order Now” button or visit the “Contact Us” page to submit your request. You can also find our email address in the “Get in Touch” section.

- Step 2: Provide details such as purity, size, quantity, and shipping address. For custom sizes, attach a drawing for technical support.

- Step 3: Submit your inquiry. Our sales or technical team will respond within 1-2 hours.

- Step 4: Confirm your requirements. We will send you an invoice for payment.

- Step 5: After payment, production begins. Once quality checks are done, we’ll pack your order and send tracking details along with the documents. Confirm receipt.

Applications of Indium Seals

Cryogenic Sealing

Indium cryogenic seals are extensively used in cryogenic applications due to their ability to remain ductile at very low temperatures. They are used in equipment like cryostats and other low-temperature research instruments.

Vacuum Sealing

The ability of indium to create a tight, reliable seal makes it ideal for ultra-high vacuum environments. Indium wire or foil is often used to create gaskets that can deform to fill any gaps, ensuring an airtight seal.

Hermetic Sealing

Indium hermetic seal is used in hermetic seals that need to be airtight and impermeable to gases and liquids. These seals are critical in various industries, including aerospace, electronics, and scientific research.

Low-Temperature and Moderate-Pressure Sealing

Indium seal vacuum are also effective in applications involving moderate pressure. Their ability to maintain a seal without significant hardening or loss of ductility makes them suitable for such environments.

Practical Considerations of Indium Seal

- Surface Preparation: Ensuring the indium is clean and free of contaminants is crucial for effective sealing. The surface must be prepared properly to avoid any disruptions in the seal properties.

- Material Compatibility: When designing seals, it’s important to match the flange materials appropriately to avoid issues during cooling or heating cycles. Stainless steel is commonly used due to its strength and tarnish resistance, but copper and brass are also options depending on the application requirements.

Packing, Transportation and Storage

Packing

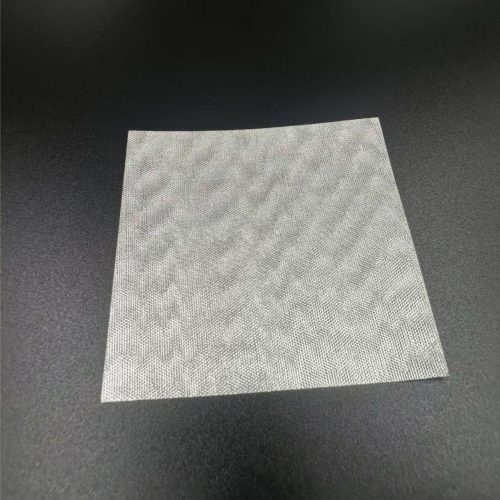

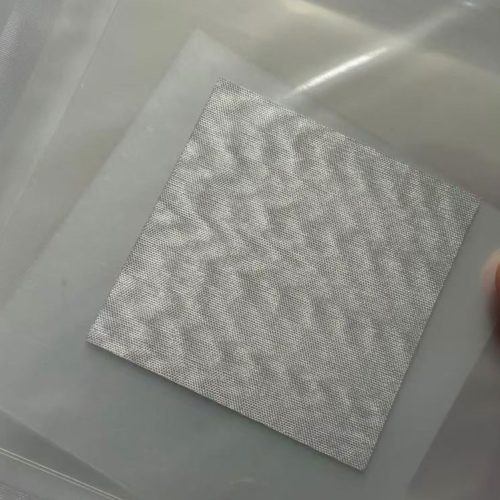

Indium Seal is clamped with a double-sided shaping plate and sealed externally in a vacuum bag, 1 piece per bag.

Transportation

By Fedex, DHL, UPS, 5-7days with door to door delivery.

By Air: 1-3days to destination airport.

By Sea:7-40days to destination port.

Storage

To extend storage time and minimize surface oxidation, please strictly seal the indium foil in its original container, ensuring a relative humidity of 55% or lower and a temperature not exceeding 22 ° C. Indium foil can also be stored in an inert atmosphere, such as a nitrogen drying oven.

Indium Recycling

Indium recycling holds significant environmental importance, contributing to the reduction of natural environmental impacts. Our company actively participates in recycling used indium scraps. You can reach out to our technical team to initiate a preliminary recycling assessment by providing photos and videos of the materials. Following the assessment, we’ll furnish a detailed report to determine the feasibility of recycling your product. Upon approval of the assessment report, we’ll guide you through the next steps to facilitate the sample submission process.

To Globally Delivery High Quality Indium Foil-Thermal Interface Materials

About our factory

As one of the leading producer in re-processing Indium Elements materials, Aster uses it’s technological expertise to R&D and produce Indium Wire, Indium Foil, Indium Gasket, Indium Seal and customize all the different size of foils, Gasket, Seal, Sheet, ribbon etc..We will continue to supply high quality products and service to support our customers with competitive market rates.

Learn moreOUR EXHIBITION IN GERMANY, USA KOREAN AND JAPAN.

GET IN TOUCH WITH US

Give us a call

General Info: +86 18673173361

Technical Support: +86 17267477981

Online Chat

WHATSAPP-CLICK GREEN BUTTON

Indium Seal

A: With over a decade of experience in manufacturing Indium Foil, we boast a distinguished reputation for excellence, supported by our stringent quality control system and a dedicated research team.

A: We usually quote within 2 hours during our business work day. If you are in urgent need of a price, please call us or let us know by email so that we will give priority to your inquiry.

A: Delivery typically occurs within 5-7 business days via express couriers such as DHL, UPS, TNT, and FedEx, while shipments by sea usually take approximately 25-35 business days to reach the destination port.

Contact Us

If you have a question or would like to be contacted by one of our team, please complete the form below.We value your questions, comments and suggestions, looking forward to hearing from you!