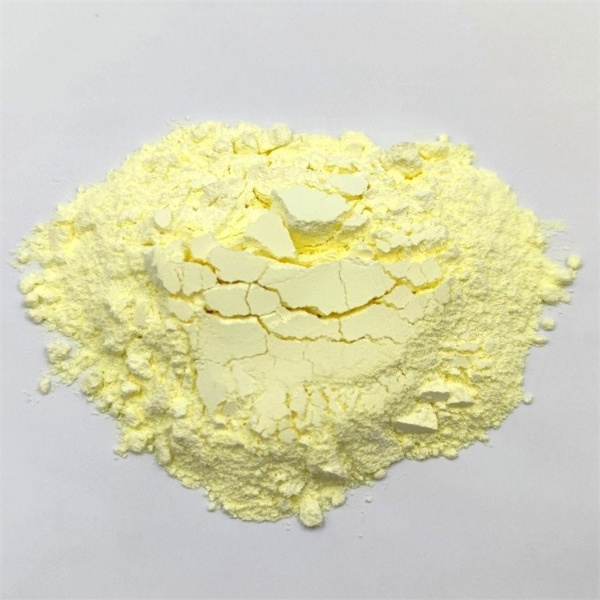

Indium oxide, with the molecular formula In2O3, is an indium oxide compound. It exists as a white or pale yellow amorphous powder in its pure form, which turns reddish-brown upon heating. Its vapor pressure (mmHg, 25°C) is less than 0.01. It is insoluble in water but soluble in hot inorganic acids.

Indium oxide is a new type of n-type transparent semiconductor functional material. It features a wide bandgap, low electrical resistivity, and high catalytic activity. It has found extensive applications in optoelectronics, gas sensors, and catalysts. When indium oxide particles reach the nanoscale, they exhibit surface effects, quantum size effects, small size effects, and macroscopic quantum tunneling effects, in addition to the aforementioned functionalities.

| Purity | 99.99% 99.999% |

| Particle Size | 1-5um |

| MF | In2O3 |

| Appearance | Light Yellow Powder |

| Cas No | 1312-43-2 |

| EINECS | 215-193-9 |

| Molecular Weight | 277.64 |

| Melting Point | 2000 ℃ |

| Boiling Point | 800℃ |

| Density | 7.18g/ml at 25℃ |

Production Methods of Indium Oxide

- High-purity metallic indium can be combusted in air or indium carbonate can be calcined to produce In2O, InO, and In2O3. Fine control of reduction conditions can yield high-purity In2O3. Alternatively, In2O3 ceramic powder with an average particle size of 20nm can be produced using spray combustion techniques.

- When burning indium hydroxide to prepare In2O3, if the temperature is too high, there is a possibility of thermal decomposition of In2O3. If the temperature is too low, it is difficult to completely dehydrate, and the resulting oxide tends to be hygroscopic. Therefore, heating temperature and time are crucial factors. Additionally, because In2O3 is easily reduced, it must be maintained in an oxidizing atmosphere frequently.

- Indium hydroxide can be calcined in air at 850°C until a constant weight is achieved to form In2O3, followed by heating at 1000°C for 30 minutes in air. Other compounds such as indium nitrate, indium carbonate, and indium sulfate can also be burned in air to obtain indium oxide (In2O3).

Indium Trioxide's Applications

- Used as materials for spectroscopic-grade reagents and electronic components.

- Applied as protective coatings for metal reflectors, semiconductor thin films for optoelectronic displays, and in the manufacture of indium salts and glass.

- It is also a primary raw material in resistive touchscreens, commonly used in fluorescent screens, glass, ceramics, and chemical reagents.

- Additionally, it finds wide application in traditional fields such as colored glass, ceramics, alkaline manganese batteries as mercury-free anticorrosive agents, and chemical reagents.

- In recent years, it has been extensively used in high-tech sectors like optoelectronics and the military, particularly suitable for processing into indium tin oxide (ITO) targets, manufacturing transparent electrodes, and materials for transparent heat reflectors used in the production of flat panel LCDs and defogging/deicing systems.

Properties and Stability

Under the presence of hydrogen or other reducing agents, heating to 400-500°C can reduce indium oxide to metallic indium or lower valence indium oxides.

At high temperatures, it decomposes into lower oxides. Additionally, it can react with metallic indium at high temperatures. While In2O3 formed at low temperatures is soluble in acids, the more thoroughly it undergoes high-temperature treatment, the less soluble it becomes, and its hygroscopicity disappears. Indium oxide (In2O3), when reduced with hydrogen at red heat, produces metallic indium.

Storage Method

Store in a tightly sealed container in a cool, dry place. Ensure good ventilation or exhaust facilities in the working area.

About our factory

As one of the leading producer in re-processing Indium materials, Aster uses it’s technological expertise to R&D and produce a range of Indium products, including Indium Foil, Indium Alloy Foil, Indium Wire, and Indium Seal. Our Indium products exported to more than 50 countries worldwide. Strategically situated in Changsha, Hunan, a major production area for Indium mines and products in the world. we are dedicated to delivering high-quality Indium products and services to support our business partners worldwide.

Learn moreGet in Touch

Give us a call

General Information: +86 18673173361

Technical Support: +86 17267477981

A: With over a decade of experience in manufacturing Indium Foil, we boast a distinguished reputation for excellence, supported by our stringent quality control system and a dedicated research team.

A: We usually quote within 2 hours during our business work day. If you are in urgent need of a price, please call us or let us know by email so that we will give priority to your inquiry.

A: Delivery typically occurs within 5-7 business days via express couriers such as DHL, UPS, TNT, and FedEx, while shipments by sea usually take approximately 25-35 business days to reach the destination port.