To Globally Delivery High Quality Indium Foil-Thermal Interface Materials

As one of the leading producer in re-processing Indium materials, Aster uses it’s technological expertise to R&D and produce a range of Indium products, including Indium Foil, Indium Alloy Foil, Indium Wire, and Indium Seal. We also specialize in customizing various sizes of foils, gaskets, seals, sheets, ribbons, and rods. Our Indium products exported to more than 50 countries worldwide, with the United States, Germany, Korea, and Japan serving as our primary markets. Strategically situated in Changsha, Hunan, a major production area for Indium mines and products in the world. we are dedicated to delivering high-quality Indium products and services to support our business partners worldwide.

Hot Products

Why Chose Us?

Focus On Clients

We aim to surpass customer expectations by providing exceptional services and products tailored to their needs. With confidence and resourcefulness, we strive to offer solutions that foster enduring trust-based relationships.

Sustainability Development

We promote individual and corporate initiatives aimed at environmental protection. This involves advocating for recycling practices for products and industrial waste both internally and with clients and suppliers. Additionally, we set goals to minimize our environmental impact.

Ongoing Enhancement

We aim for excellence in every facet of our operations, aspiring to be recognized as the leading producer in our industry. To achieve this, we are committed to continuously enhancing our skills and elevating the quality of our products and services.

Integrity

We uphold the utmost integrity, honoring our commitments, abiding by both the laws and their intentions, and treating every individual we engage with in business with respect and dignity.

Manufacturing Process

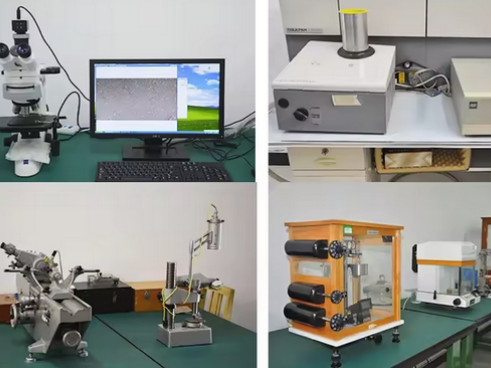

1. Raw Materials Inspection

Sampling to test the purity to check the quality is qualified and meet the 4N5 OR 5N standard.

2. Processing Steps

To produce the foil, wire and rod requires some specific steps to ensure the materials didnot get oxidation, and stay good thickness uniformity.

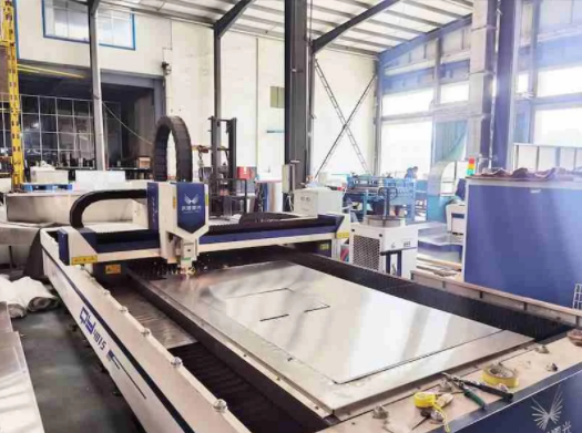

3. Cut the Materials

Using laser cutting machine to precisely cut the Indium materials to make sure indium foil or indium sheet is clean and smooth.

4. QC and Packing

After checking the products meet the specific standard then start the packing process.

Showcasing Our Diverse Portfolio of Success Stories

What our clients say

News and Updates

Contact Us

If you have a question or would like to be contacted by one of our team, please complete the form below.We value your questions, comments and suggestions, looking forward to hearing from you!