Indium-Vakuumdichtung zeichnet sich als hervorragendes Material für die Herstellung heliumdichter hermetischer Dichtungen aus, die Metalle und nichtmetallische Substrate wie Glas und Keramik verbinden. Seine Vielseitigkeit erstreckt sich auch auf kryogene Umgebungen, Vakuumpumpen und hitzeempfindliche Bereiche, wo es eine zuverlässige Eindämmung gewährleistet.

Wenn Indium als Dichtungsmittel dient, geht es eine chemische Verbindung mit den Oberflächen ein, die es verbindet, was sich von der bloßen Barrierebildung anderer Dichtungsmaterialien unterscheidet. Indiumdichtungen sind insbesondere widerstandsfähig gegen mechanische Stöße, Vibrationen und extreme Temperaturen, was sie für anspruchsvolle Anwendungen unverzichtbar macht.

Eine inhärente Eigenschaft von Indium ist seine Tendenz, auf seiner Oberfläche einen Oxidfilm zu bilden. Um eine makellose Verbindung mit einem Substrat herzustellen, muss dieser Film durch Kompression und plastische Verformung zerstört werden. Dieser Prozess, der durch die Formbarkeit von Indium erleichtert wird, läuft selbst bei kryogenen Temperaturen problemlos ab und gewährleistet eine wirksame Abdichtung.

Die Qualität einer Indium-Dichtung hängt von mehreren Faktoren ab:

- Reinheit und Sauberkeit: Optimale Indium-Reinheitsgrade von 99,991 TP3T werden bevorzugt, obwohl bestimmte Anwendungen eine Indium-Reinheit von 99,9991 TP3T erfordern. Verunreinigungen, insbesondere organische Verbindungen, sollten durch Entfetten entfernt werden. Oberflächenoxide können durch ein kurzes Eintauchen in 501 TP3T-Salzsäure und anschließendes Spülen in deionisiertem Wasser entfernt werden.

- Oberflächenvorbereitung: Alle Oberflächen müssen gründlich gereinigt und getrocknet werden. Glas- und Keramikoberflächen müssen mit Chrom- und Schwefelsäure behandelt werden, gefolgt von einer Spülung mit Salzsäure und deionisiertem Wasser. Indiummetalloberflächen können blank, mit Indium vorverzinnt oder mit Indium oder Silber beschichtet sein. Die Oberflächenbearbeitung muss sorgfältig erfolgen, ohne übermäßiges Polieren oder abrasive Veränderungen.

- Dicke und Form von Indium: Die Dicke der Indiumdichtung variiert je nach Oberfläche und Druckkraft. Bei Anwendungen mit Indium-O-Ring-Nuten sollte die Indiumdichtung die Abmessungen der Nut bei Kompression um 5-15% überschreiten. Überlappende Indiumsegmente können in bestimmten Szenarien eine durchgehende Unterlegscheibe ersetzen. Gut geformte Dichtungen weisen Leckraten von unter 2 x 10-7 Torr x Liter/Sek. auf.

Durch die Einhaltung sorgfältiger Verfahren bei der Indiumauswahl, Oberflächenvorbereitung und Dichtungskonfiguration können Ingenieure die Zuverlässigkeit und Wirksamkeit hermetischer Dichtungen in kritischen Anwendungen sicherstellen.

Physikalische Eigenschaften

Eine der bemerkenswertesten physikalischen Eigenschaften von Indium ist seine außergewöhnliche Duktilität und Formbarkeit. Indium besitzt eine Mohshärte von nur 1,2, die deutlich niedriger ist als die von Kupfer (2,5-3) und Aluminium (2-2,9), wodurch es viel weicher und leichter zu verformen ist.

Der Schmelzpunkt ist mit 156,6 °C relativ niedrig, sodass es sich leicht in verschiedene Formen und Größen gießen lässt, beispielsweise in Vorformlinge und Drähte, um für spezielle Dichtungsanwendungen geeignet zu sein.

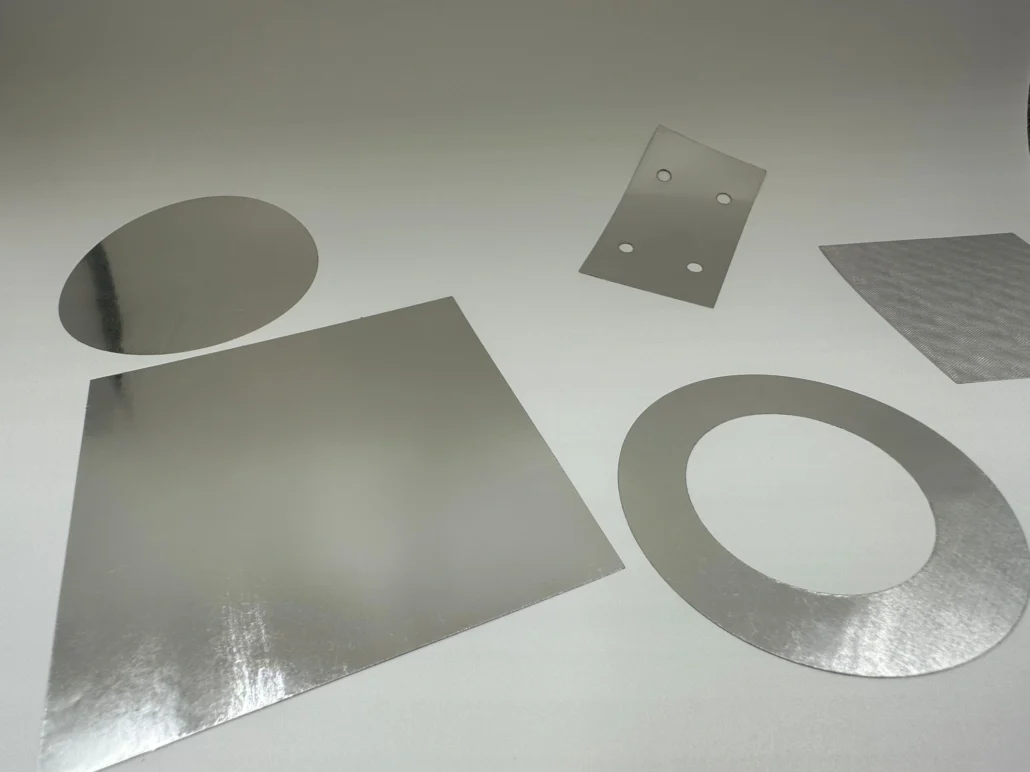

Indium kann in Dicken von dünn (0,008 Zoll) bis dick (0,062 Zoll) hergestellt werden, abhängig von den Passflächen und den erforderlichen Druckkräften.

Chemische Eigenschaften

Dichtungseigenschaften

IndiumDie Fähigkeit, hermetische Dichtungen ohne Hitze zu bilden, ist besonders in Umgebungen von Vorteil, in denen Hitze oder Lötflussmittel Probleme wie Ausgasung verursachen könnten.

Bei Verwendung als Dichtungsmittel geht Indium eine chemische Bindung mit den Oberflächen ein, die es verbindet, und bietet so bessere Dichtungseigenschaften als andere Dichtungsmaterialien, die lediglich als Barriere wirken.

Dank dieser Eigenschaft behalten Indiumdichtungen ihre Integrität sogar bei mechanischen Stößen, Vibrationen und extremen Temperaturen, was sie für anspruchsvolle Anwendungen unverzichtbar macht.

Oberflächenvorbereitung

Die richtige Oberflächenvorbereitung ist entscheidend für die Erzielung hochwertiger Indiumversiegelungen. Oberflächen müssen gründlich gereinigt und getrocknet werden, wobei für verschiedene Materialien spezielle Behandlungen erforderlich sind. Beispielsweise sollten Glas- und Keramikoberflächen mit Chrom- und Schwefelsäure behandelt und anschließend mit Salzsäure und deionisiertem Wasser abgespült werden.

Indiummetall Um eine optimale Bindung zu gewährleisten, müssen die Oberflächen möglicherweise vorverzinnt oder mit Indium oder Silber beschichtet werden.

Die Formbarkeit von Indium erleichtert die Entfernung von Oberflächenoxiden durch Kompression und plastische Verformung und gewährleistet so eine wirksame Abdichtung auch bei kryogenen Temperaturen.

Die Vielseitigkeit von Indium erstreckt sich auch auf seine Verwendung bei der Herstellung heliumdichter hermetischer Dichtungen, die Metalle und nichtmetallische Substrate wie Glas und Keramik verbinden können. Dies macht Indium zu einem unverzichtbaren Material für Anwendungen, die eine zuverlässige Leistung in Vakuumpumpen, kryogenen Umgebungen und anderen wärmeempfindlichen Bereichen erfordern.

Indium-Vakuumversiegelungstechnologie

Indium-Vakuumversiegelungstechnologie nutzt die einzigartigen Eigenschaften von Indium, um zuverlässige und effektive Dichtungen in einer Vielzahl von Anwendungen zu schaffen, darunter kryogene Umgebungen, Vakuumpumpen und wärmeempfindliche Bereiche.

Diese Technologie wird besonders wegen ihrer Fähigkeit geschätzt, heliumdichte hermetische Dichtungen zu bilden und sowohl metallische als auch nichtmetallische Substrate wie Glas und Keramik zu überbrücken.

Eigenschaften und Vorteile

Indium zeichnet sich durch seinen niedrigen Schmelzpunkt sowie seine hohe Formbarkeit und Duktilität aus, was es zu einem idealen Material für die Vakuumversiegelung macht.

Im Gegensatz zu Dichtungen aus anderen Materialien, die lediglich eine Barriere bilden, geht Indium eine chemische Bindung mit den Oberflächen ein, die es verbindet, und verbessert so die Widerstandsfähigkeit der Dichtung gegen mechanische Stöße, Vibrationen und niedrige Temperaturen.

Eine bemerkenswerte Eigenschaft von Indium ist seine Tendenz, auf seiner Oberfläche einen Oxidfilm zu bilden. Um eine makellose Verbindung mit einem Substrat herzustellen, muss dieser Oxidfilm durch Kompression und plastische Verformung zerstört werden, ein Prozess, der durch die Formbarkeit des Metalls erleichtert wird.

Dadurch ist eine wirksame Abdichtung auch bei kryogenen Temperaturen ohne die Notwendigkeit einer Wärmezufuhr gewährleistet.

Anwendungen

Indium-Vakuumdichtungen haben aufgrund ihrer einzigartigen Eigenschaften und ihrer Fähigkeit, unter extremen Bedingungen effektiv zu funktionieren, ein breites Anwendungsspektrum. Aufgrund ihrer Vielseitigkeit eignen sich Indiumdichtungen für Branchen von der Luft- und Raumfahrt über die Automobilindustrie bis hin zum medizinischen und industriellen Sektor.

Luft- und Raumfahrt sowie Automobil

In der Luft- und Raumfahrt sowie im Automobilsektor werden Indiumdichtungen aufgrund ihrer hervorragenden Dichtungseigenschaften und ihrer Fähigkeit, ein Vakuum unter Hochdruck- und Hochtemperaturbedingungen aufrechtzuerhalten, eingesetzt. Dadurch wird die Integrität von Komponenten und Systemen gewährleistet, die in rauen Umgebungen betrieben werden.

Medizin und Industrie

Die medizinischen und industriellen Anwendungen von Indium-Vakuumdichtungen sind umfangreich. Indiumdichtungen werden in medizinischen Geräten und Ausrüstungen verwendet, die eine hohe Reinheit und Zuverlässigkeit erfordern, wie etwa Diagnoseinstrumente und Bioimplantate. So basieren beispielsweise die personalisierte Medizin und die Point-of-Care-Diagnostik (POC) oft auf Geräten, die auf molekularer Ebene arbeiten, wo die präzise Funktion der Dichtungen von entscheidender Bedeutung ist.

Intelligente Technologieintegration

Ein wachsender Trend in Indium-Dichtungsdesign ist die Integration intelligenter Technologie. Mit der Ausbreitung des Internets der Dinge (IoT) steigt die Nachfrage nach Dichtungslösungen, die verschiedene Prozesse in Echtzeit überwachen und steuern können. Indiumdichtungen eignen sich aufgrund ihrer einzigartigen Eigenschaften gut für diese Anwendungen und können in einer Vielzahl von Szenarien eingesetzt werden. Durch die Integration von Sensoren und anderen intelligenten Geräten in Indiumdichtungen können Hersteller effizientere und intelligentere Dichtungslösungen schaffen.

Oberflächenanalytische Techniken

Im Bereich der Ultrahochvakuum-Anwendungen (UHV) sind Indiumdichtungen entscheidend für die Aufrechterhaltung der Vakuumbedingungen, die für Oberflächenanalysetechniken erforderlich sind. Zu diesen Techniken gehören Röntgen-Photoelektronenspektroskopie (XPS), Auger-Elektronenspektroskopie (AES), Sekundärionen-Massenspektrometrie (SIMS) und andere. UHV-Bedingungen sind unerlässlich, um Oberflächenkontaminationen während dieser Analysen zu reduzieren. Indiumdichtungen helfen dabei, die strengen Vakuumbedingungen zu erreichen, die für diese hochpräzisen Techniken erforderlich sind, und ermöglichen genaue und zuverlässige Messungen.

Neue Technologien

Auch neue Technologien wie Antifouling-Eigenschaften, Bioimplantate und Diagnosegeräte profitieren vom Einsatz von Indium-Vakuumdichtungen. Diese Anwendungen erfordern ein grundlegendes Verständnis von Bioschnittstellen und die Fähigkeit, sterile und kontaminationsfreie Umgebungen aufrechtzuerhalten. Indiumdichtungen leisten einen wesentlichen Beitrag zu diesen Bereichen, indem sie zuverlässige Dichtungslösungen bieten, die den strengen Anforderungen moderner Technologie gerecht werden.

Zusammenfassung

Ein Indium-Vakuumdichtung ist eine spezielle Dichtungstechnologie, die die einzigartigen Eigenschaften von Indium nutzt, einem Post-Übergangsmetall, das für seine Formbarkeit, Duktilität und Fähigkeit zur Bildung hermetischer Dichtungen bekannt ist. Indium-Vakuumdichtungen werden wegen ihrer Fähigkeit, heliumdichte hermetische Dichtungen zu bilden, sehr geschätzt, indem sie eine chemische Bindung mit den Oberflächen eingehen, die sie verbinden. Diese chemische Bindung fungiert nicht nur als Barriere, sondern gewährleistet hervorragende Dichtungseigenschaften, die mechanischen Stößen, Vibrationen und extremen Temperaturen standhalten.