When it comes to optimizing thermal conductivity in high-temperature and cryogenic applications, two standout solutions emerge: Indium Foil and Liquid Metal Thermal Paste. Let’s delve into their unique properties and applications to understand their comparative advantages.

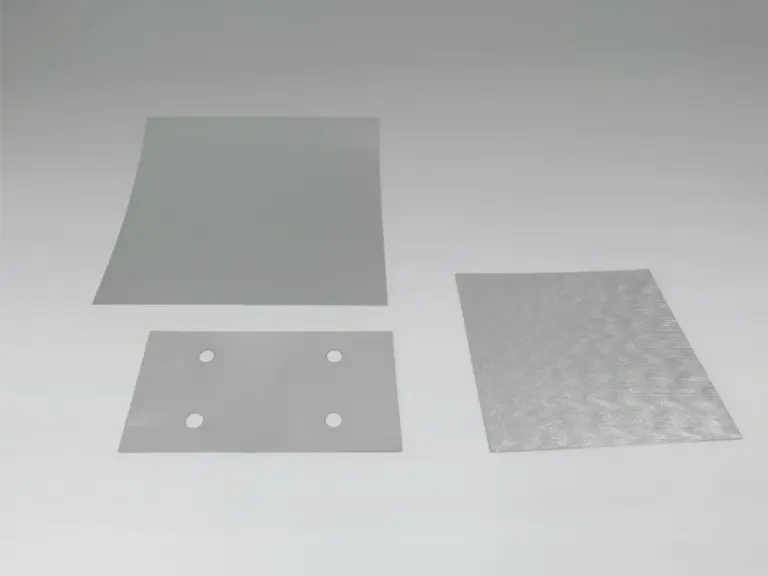

Indium Foil, crafted from pure Indium Ingot, boasts exceptional malleability and a remarkable thermal conductivity of 86W/mK. Its versatility extends to serving as a gasket for pressure and vacuum sealing needs, enhancing thermal contact areas, and preventing sensor detachment due to vibration. Ideal for cryogenic pumps, high vacuum systems, and diverse sealing applications, Indium Foil remains pliable even in low temperatures.

On the other hand, Liquid Metal Thermal Paste, a blend of non-toxic metals such as gallium, indium, tin, zinc, and silver, revolutionizes heat dissipation with its liquid form at room temperature. With superior thermal and electrical conductivity surpassing 70W/m·K, it ensures efficient heat transfer while maintaining stability. Its fluid nature facilitates complete interface coverage, minimizing thermal resistance, and it exhibits compatibility with copper and stainless steel, ensuring device safety and longevity.

Liquid Metal Thermal Paste’s versatility extends to flexible circuit printing, wires, thermal control, microelectrodes, and beyond, making it an ideal replacement for traditional silicone grease in CPU/GPU heat dissipation. Compliant with EU RoHS standards and suitable for various applications including thermal cooling systems, biomedical devices, and flexible printed circuit boards, it offers a safe and effective solution for thermal management needs.

In terms of price, the Indium Foil price can be varied from USD35/PC-USD150/PC while Liquid metal thermal paste price is like USD20/1.5G for one time uses. If you wanna know more details of the price, you can contact us for the formal quotation.

In summary, while Indium Foil excels in specific sealing applications and cryogenic environments, Liquid Metal Thermal Paste emerges as a versatile, high-performance solution for efficient heat dissipation across diverse industries and applications. Whether it’s optimizing heat transfer in high-temperature environments or enhancing thermal conductivity in electronic devices, both solutions offer unique benefits tailored to specific needs.