Joint sous vide en indium se distingue comme un matériau supérieur pour créer des joints hermétiques étanches à l’hélium, reliant les métaux et les substrats non métalliques comme le verre et la céramique. Sa polyvalence s'étend aux environnements cryogéniques, aux pompes à vide et aux zones sensibles à la chaleur, où il assure un confinement fiable.

Lorsque l'indium sert de mastic, il initie une liaison chimique avec les surfaces qu'il connecte, distincte de la simple formation de barrière d'autres matériaux de joint. Les joints en indium font notamment preuve de résilience aux chocs mécaniques, aux vibrations et aux températures extrêmes, ce qui les rend indispensables dans les applications exigeantes.

Une propriété inhérente de l’indium est sa tendance à développer un film d’oxyde à sa surface. Pour établir une liaison parfaite avec un substrat, ce film doit être rompu par compression et déformation plastique. Ce processus, facilité par la malléabilité de l'indium, se produit facilement même à des températures cryogéniques, garantissant une étanchéité efficace.

La qualité d'un sceau d'indium dépend de plusieurs facteurs :

- Pureté et propreté : Des niveaux optimaux de pureté d'indium de 99,99% sont préférés, bien que certaines applications exigent une pureté d'indium de 99,999%. Les contaminants, en particulier les composés organiques, doivent être éliminés par dégraissage. Les oxydes de surface peuvent être éliminés par un bref trempage dans l'acide chlorhydrique 50%, suivi d'un rinçage à l'eau déminéralisée.

- Préparation de surface: Toutes les surfaces doivent être soigneusement nettoyées et séchées. Les surfaces en verre et en céramique nécessitent un traitement avec des acides chromique et sulfurique, suivi d'un rinçage à l'acide chlorhydrique et à l'eau déminéralisée. Les surfaces en métal indium peuvent être nues, pré-étamées avec de l'indium ou plaquées avec de l'indium ou de l'argent. La finition de la surface doit être soigneusement exécutée, sans polissage excessif ni altération abrasive.

- Épaisseur et forme de l'indium : L’épaisseur du joint Indium varie en fonction de la surface et de la force de compression. Pour les applications de rainure de joint torique en Indium, le joint en Indium doit dépasser les dimensions de la rainure de 5-15% lorsqu'il est comprimé. Des segments d'indium qui se chevauchent peuvent remplacer une rondelle continue dans certains scénarios. Les joints bien formés présentent des taux de fuite inférieurs à 2 x 10-7 torr x litre/sec.

En adhérant à des procédures méticuleuses pour la sélection de l'indium, la préparation des surfaces et la configuration des joints, les ingénieurs peuvent garantir la fiabilité et l'efficacité des joints hermétiques dans les applications critiques.

Propriétés physiques

L’une des propriétés physiques les plus remarquables de indium L'indium se distingue par sa ductilité et sa malléabilité exceptionnelles. L'indium possède une dureté Mohs de seulement 1,2, nettement inférieure à celle du cuivre (2,5-3) et de l'aluminium (2-2,9), ce qui le rend beaucoup plus mou et plus facile à déformer.

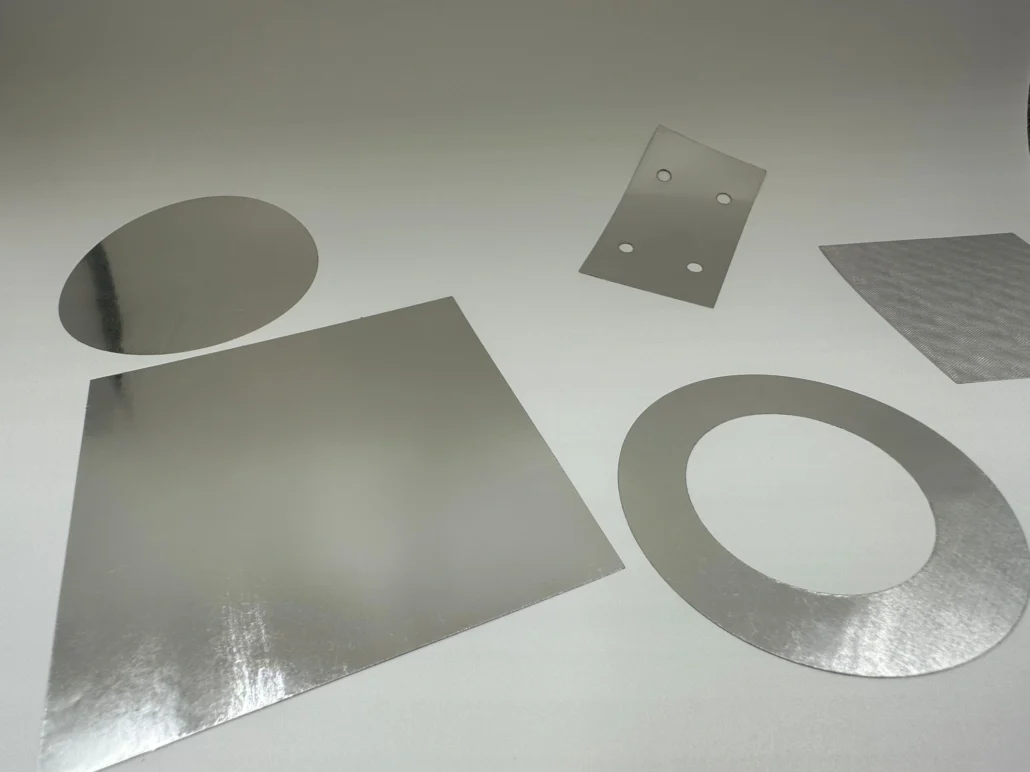

Son point de fusion relativement bas de 156,6°C lui permet d'être facilement moulé dans diverses formes et tailles, telles que des préformes et des fils, pour s'adapter à des applications d'étanchéité spécifiques.

L'indium peut être fabriqué dans des épaisseurs allant de mince (0,008 pouce) à épaisse (0,062 pouce), en fonction des surfaces de contact et des forces de compression requises.

Propriétés chimiques

Caractéristiques d'étanchéité

IndiumLa capacité de à former des joints hermétiques sans avoir besoin de chaleur est particulièrement avantageuse dans les environnements où la chaleur ou le flux de soudure peuvent causer des problèmes tels que le dégazage.

Lorsqu'il est utilisé comme produit d'étanchéité, l'indium initie une liaison chimique avec les surfaces qu'il relie, offrant des capacités d'étanchéité supérieures par rapport aux autres matériaux de joint qui agissent simplement comme des barrières.

Cette propriété permet aux joints en indium de conserver leur intégrité même en cas de chocs mécaniques, de vibrations et de températures extrêmes, ce qui les rend indispensables dans les applications exigeantes.

Préparation de surface

Une préparation adéquate de la surface est essentielle pour obtenir des joints d'indium de haute qualité. Les surfaces doivent être soigneusement nettoyées et séchées, avec des traitements spécifiques pour différents matériaux. Par exemple, les surfaces en verre et en céramique doivent être traitées avec des acides chromique et sulfurique, suivis d'un rinçage à l'acide chlorhydrique et à l'eau déionisée.

Indium métallique les surfaces peuvent nécessiter un pré-étamage ou un placage à l'indium ou à l'argent pour assurer une liaison optimale.

L'élimination des oxydes de surface par compression et déformation plastique est facilitée par la malléabilité de l'indium, assurant une étanchéité efficace même à des températures cryogéniques.

La polyvalence de l'indium s'étend à son utilisation dans la formation de joints hermétiques étanches à l'hélium, capables de relier des métaux et des substrats non métalliques comme le verre et la céramique. Cela fait de l'indium un matériau essentiel dans les applications nécessitant des performances fiables dans les pompes à vide, les environnements cryogéniques et d'autres zones sensibles à la chaleur.

Technologie d'étanchéité sous vide à l'indium

Technologie d'étanchéité sous vide à l'indium exploite les propriétés uniques de l'indium pour créer des joints fiables et efficaces dans une variété d'applications, notamment les environnements cryogéniques, les pompes à vide et les zones sensibles à la chaleur.

Cette technologie est particulièrement appréciée pour sa capacité à former des joints hermétiques étanches à l’hélium, reliant des substrats métalliques et non métalliques comme le verre et la céramique.

Propriétés et avantages

Indium se caractérise par son bas point de fusion, sa grande malléabilité et sa ductilité, qui en font un matériau idéal pour le scellage sous vide.

Contrairement aux joints fabriqués à partir d’autres matériaux qui ne forment qu’une barrière, l’indium crée une liaison chimique avec les surfaces qu’il relie, améliorant ainsi la résilience du joint contre les chocs mécaniques, les vibrations et les basses températures.

L'indium se caractérise par sa tendance à former un film d'oxyde à sa surface. Pour établir une liaison parfaite avec un substrat, ce film d'oxyde doit être rompu par compression et déformation plastique, un processus facilité par la malléabilité du métal.

Cela garantit une étanchéité efficace même à des températures cryogéniques sans besoin de chaleur.

Applications

Joints sous vide en indium Les joints en indium sont adaptés à un large éventail d'applications en raison de leurs propriétés uniques et de leur capacité à fonctionner efficacement dans des conditions extrêmes. La polyvalence des joints en indium les rend adaptés à des secteurs allant de l'aérospatiale et de l'automobile aux secteurs médical et industriel.

Aérospatiale et automobile

Dans les secteurs de l'aéronautique et de l'automobile, les joints en indium sont utilisés pour leurs excellentes propriétés d'étanchéité et leur capacité à maintenir le vide dans des conditions de haute pression et de haute température. Cela garantit l'intégrité des composants et des systèmes qui fonctionnent dans des environnements difficiles.

Médical et industriel

Les applications médicales et industrielles des joints sous vide en indium sont nombreuses. Les joints en indium sont utilisés dans les dispositifs et équipements médicaux qui nécessitent une pureté et une fiabilité élevées, tels que les outils de diagnostic et les bioimplants. Par exemple, la médecine personnalisée et les diagnostics au point de service (POC) reposent souvent sur des dispositifs qui fonctionnent au niveau moléculaire, où le fonctionnement précis des joints est crucial.

Intégration de technologies intelligentes

Une tendance croissante dans conception de joint d'indium L'intégration de la technologie intelligente est essentielle. Avec l'expansion de l'Internet des objets (IoT), la demande de solutions d'étanchéité capables de surveiller et de contrôler divers processus en temps réel augmente. Les joints en indium sont bien adaptés à ces applications en raison de leurs propriétés uniques, qui leur permettent d'être utilisés dans un large éventail de scénarios. En incorporant des capteurs et d'autres dispositifs intelligents dans les joints en indium, les fabricants peuvent créer des solutions d'étanchéité plus efficaces et plus intelligentes.

Techniques d'analyse de surface

Dans le domaine des applications à ultra-vide (UHV), les joints en indium sont essentiels pour maintenir les conditions de vide nécessaires aux techniques d'analyse de surface. Ces techniques comprennent la spectroscopie de photoélectrons à rayons X (XPS), la spectroscopie d'électrons Auger (AES), la spectrométrie de masse d'ions secondaires (SIMS) et d'autres. Les conditions UHV sont essentielles pour réduire la contamination de surface lors de ces analyses. Les joints en indium aident à atteindre les conditions de vide rigoureuses requises pour ces techniques de haute précision, permettant des mesures précises et fiables.

Technologies émergentes

Les technologies émergentes telles que les propriétés antisalissures, les bioimplants et les dispositifs de diagnostic bénéficient également de l'utilisation de joints sous vide en indiumCes applications nécessitent une compréhension fondamentale des biointerfaces et la capacité à maintenir des environnements stériles et exempts de contaminants. Les joints en indium contribuent de manière significative à ces domaines en fournissant des solutions d'étanchéité fiables qui répondent aux exigences rigoureuses de la technologie moderne.

Résumé

Un joint sous vide en indium est une technologie d'étanchéité spécialisée qui exploite les propriétés uniques de l'indium, un métal post-transition connu pour sa malléabilité, sa ductilité et sa capacité à former des joints hermétiques. Les joints sous vide en indium sont très appréciés pour leur capacité à former des joints hermétiques étanches à l'hélium en se liant chimiquement aux surfaces qu'ils connectent. Cette liaison chimique, au lieu de simplement agir comme une barrière, assure des capacités d'étanchéité supérieures qui résistent aux chocs mécaniques, aux vibrations et aux températures extrêmes.