क्या हैं इंडियम इंटरफ़ेस सामग्री?

इंडियम इंटरफ़ेस सामग्री थर्मल प्रबंधन अनुप्रयोगों में उपयोग किए जाने वाले विशेष समाधान हैं, जो गर्मी हस्तांतरण को बढ़ाने और इलेक्ट्रॉनिक और औद्योगिक प्रणालियों में इष्टतम प्रदर्शन सुनिश्चित करने के लिए उपयोग किए जाते हैं। ये सामग्रियाँ दो सतहों के बीच विश्वसनीय, कुशल और टिकाऊ सील बनाने में महत्वपूर्ण भूमिका निभाती हैं, विशेष रूप से ऐसे वातावरण में जहाँ हर्मेटिक सीलिंग या क्रायोजेनिक संगतता की आवश्यकता होती है।

थर्मल इंटरफेस को समझना

थर्मल इंटरफ़ेस दो वस्तुओं के बीच कनेक्शन बिंदु है जिसके माध्यम से थर्मल ऊर्जा प्रवाहित होती है। उदाहरणों में हीट सिंक और थर्मोइलेक्ट्रिक मॉड्यूल (TEC) के बीच जंक्शन शामिल है। इन इंटरफेस पर अधिकतम थर्मल चालकता प्राप्त करना कुशल गर्मी अपव्यय के लिए आवश्यक है, और इंडियम कई अनुप्रयोगों के लिए एक आदर्श समाधान प्रदान करता है।

इंडियम की प्रभावशीलता के पीछे का विज्ञान

यहां तक कि जब दो सतहें सपाट और चिकनी दिखाई देती हैं, तो वे सूक्ष्म चोटियों और घाटियों से भरी होती हैं, जिससे उनका वास्तविक संपर्क क्षेत्र लगभग 5% तक कम हो जाता है। इंडियम के अद्वितीय गुण, जैसे कि इसकी लचीलापन और तापीय चालकता, इसे इन अंतरालों को प्रभावी ढंग से भरने की अनुमति देते हैं, जिससे लगभग पूर्ण तापीय इंटरफ़ेस बनता है और गर्मी हस्तांतरण में काफी सुधार होता है।

थर्मल प्रबंधन के लिए इंडियम क्यों चुनें?

इंडियम अपने असाधारण गुणों के कारण थर्मल इंटरफ़ेस सामग्रियों में सबसे अलग है। क्रायोजेनिक तापमान पर भी, संपीड़न के तहत सतहों के साथ रासायनिक बंधन बनाने की इसकी क्षमता इसे महत्वपूर्ण अनुप्रयोगों के लिए एक विश्वसनीय विकल्प बनाती है। इसके अतिरिक्त, ऑक्सीकरण, कंपन और यांत्रिक आघात के प्रति इंडियम का प्रतिरोध दीर्घकालिक स्थिरता सुनिश्चित करता है।

इंडियम इंटरफ़ेस सामग्रियों के प्रमुख अनुप्रयोग

इंडियम का उपयोग इलेक्ट्रॉनिक्स, एयरोस्पेस, क्रायोजेनिक्स और चिकित्सा उपकरणों सहित कई उद्योगों में किया जाता है। सामान्य अनुप्रयोगों में शामिल हैं:

- वैक्यूम पंप और क्रायोजेनिक प्रणालियों में सीलिंग।

- इलेक्ट्रॉनिक मॉड्यूल में ताप-संवेदनशील क्षेत्र।

- कांच, सिरेमिक और धातु घटकों के लिए इंटरफेस।

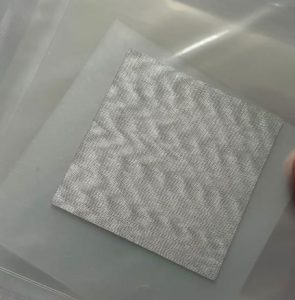

इंडियम इंटरफ़ेस सामग्री के प्रकार

विशिष्ट अनुप्रयोग आवश्यकताओं को पूरा करने के लिए इंडियम का उपयोग विभिन्न रूपों में किया जा सकता है। इनमें शामिल हैं:

- इंडियम शीट और फ़ॉइल: अनुकूलन योग्य मोटाई के साथ फ्लैट सील बनाने के लिए आदर्श।

- प्री-टिन्ड इंडियमबेहतर बंधन के लिए इंडियम या चांदी की एक परत के साथ लेपित।

- इंडियम ओ-रिंग और गैस्केट: सटीक सीलिंग अनुप्रयोगों के लिए इंजीनियर।

इंडियम सील के लिए सतहों की तैयारी

इंडियम सील की प्रभावशीलता सुनिश्चित करने के लिए उचित सतह की तैयारी महत्वपूर्ण है। इस प्रक्रिया में शामिल हैं:

- सफाई: डीग्रीजिंग सॉल्वैंट्स या अल्ट्रासोनिक सफाई का उपयोग करके तेल और मलबे को हटा दें।

- चमकानेअपघर्षक पाउडर या मशीनिंग का उपयोग करके एक अच्छी फिनिश प्राप्त करें।

- एचिंगमहत्वपूर्ण अनुप्रयोगों के लिए, इंडियम पर ऑक्साइड परतों को 50% हाइड्रोक्लोरिक एसिड में डुबोकर हटाया जा सकता है।

इंडियम इंटरफ़ेस सामग्री के लाभ

इंडियम पारंपरिक थर्मल इंटरफ़ेस सामग्रियों की तुलना में कई लाभ प्रदान करता है, जैसे:

- उच्च तापीय चालकता.

- दबाव के तहत उत्कृष्ट यांत्रिक अनुपालन।

- क्रायोजेनिक और उच्च तापमान वातावरण के साथ अनुकूलता।

- न्यूनतम प्रदर्शन गिरावट के साथ दीर्घकालिक स्थायित्व।

इंडियम सील की गुणवत्ता को प्रभावित करने वाले कारक

इंडियम सील का प्रदर्शन कई कारकों पर निर्भर करता है, जिनमें शामिल हैं:

- पवित्रताअधिकांश अनुप्रयोगों के लिए न्यूनतम शुद्धता 99.99% की अनुशंसा की जाती है।

- सील डिजाइनउचित आकार और संपीड़न प्रभावी सीलिंग सुनिश्चित करते हैं।

- अनुप्रयोग वातावरणतापमान और यांत्रिक तनाव पर विचार।

इंडियम बनाम अन्य थर्मल इंटरफ़ेस सामग्री

इंडियम कई पहलुओं में थर्मल ग्रीस और पैड जैसे पारंपरिक TIM से बेहतर है। ग्रीस के विपरीत जो समय के साथ खराब हो सकते हैं, इंडियम बेहतर थर्मल और मैकेनिकल गुणों के साथ एक स्थिर, पुन: प्रयोज्य समाधान प्रदान करता है।

निष्कर्ष: थर्मल इंटरफेस में इंडियम का भविष्य

इंडियम इंटरफ़ेस सामग्री थर्मल चालकता, लचीलापन और विश्वसनीयता के अपने बेजोड़ संयोजन के साथ थर्मल प्रबंधन के क्षेत्र में क्रांति ला रही है। गर्मी हस्तांतरण को अनुकूलित करके और टिकाऊ सील सुनिश्चित करके, इंडियम इलेक्ट्रॉनिक कूलिंग, क्रायोजेनिक्स और उससे आगे की प्रगति का मार्ग प्रशस्त कर रहा है।